Maptek showcases innovative through-seam blast technology at ISEE

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

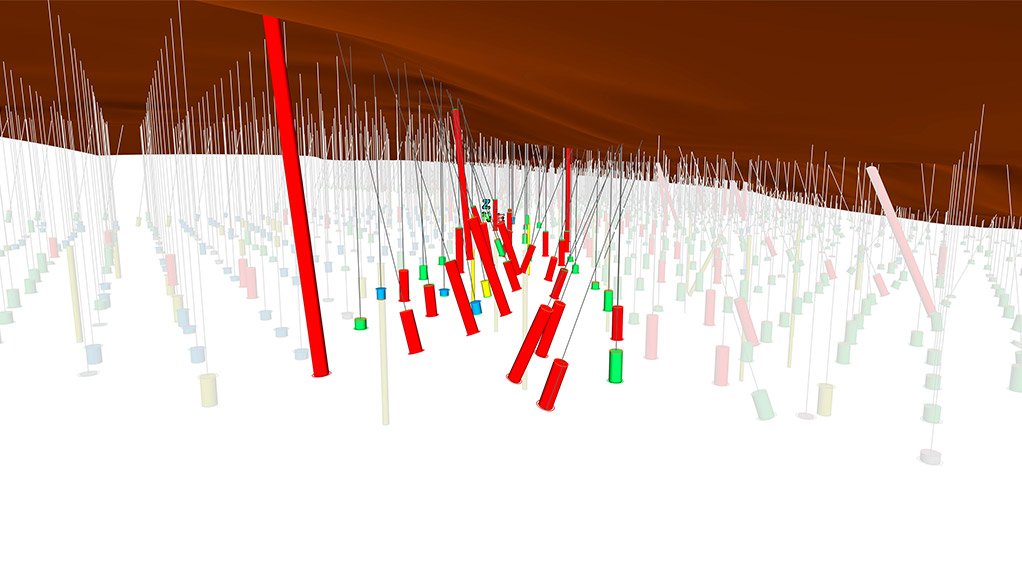

Company Announcement -Maptek will showcase its innovative through-seam blast technology at the annual conference on explosives and blasting techniques, ISEE, in Las Vegas next week. Maptek BlastLogic easily handles critical design factors to ensure that coal seams remain intact even during complicated blasts where there is minimal room for error. Booth visitors will be able to see firsthand the ways that BlastLogic can monitor drill access, explosives loading around coal and timing for each bench in through-seam blasts. Tracking KPIs across all drill & blast activities streamlines quality assurance and quality control.

Snapshots of historical blasts guide selection of optimum powder factor and dictate drill burden and spacing that take into account waste and coal margins. Explosives loading rules dictate how much stemming should be loaded through coal and at the surface, and the type of explosives for wet and dry conditions. ‘BlastLogic links blast designs directly with the geology model,’ said Maptek Blast Management specialist Steve Putt. ‘This helps ensure placement of detonators and explosives columns with centimetre accuracy to prevent unwanted dilution. Every hole can be tracked in detail across a bench and a project.’ ‘If drills do not have access to where holes are needed, the blast is off to a bad start. Through-seam explosives loading is unique for every hole and specific loading instructions are based on where the coal is in each hole.’

‘Obviously good design is just one part of the coal recovery equation,’ he added. ‘Any variation from the designed load plan can cause dilution and ultimately reduce revenue. BlastLogic tracks execution progress to ensure that learnings can be passed along for future blasts.’ Direct interface to site drill navigation systems automatically retrieves as-drilled data. With live information, engineers can review any changes to the explosives loading plan immediately the holes are drilled.

Drilling mistakes can be corrected by adjusting explosives loading. Loading mistakes can be mitigated by adjusting the blast timing.

‘It may take several attempts to optimise the blast’, Putt concluded. ‘Keeping good records guides long-term improvement. A robust, easy to use tracking system such as BlastLogic is critical to productivity. Substantial time is saved on data formatting and entry in various systems, allowing engineers to focus on drill & blast planning and compliance.’

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation