Local manufacturers improve quality

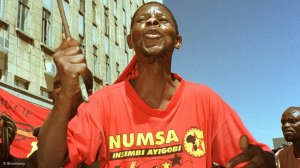

LOCAL CAPABILITIES Government’s Renewable Energy Independent Power Producer Procurement Programme has presented extensive growth opportunities for local manufacturers

Photo by Bloomberg

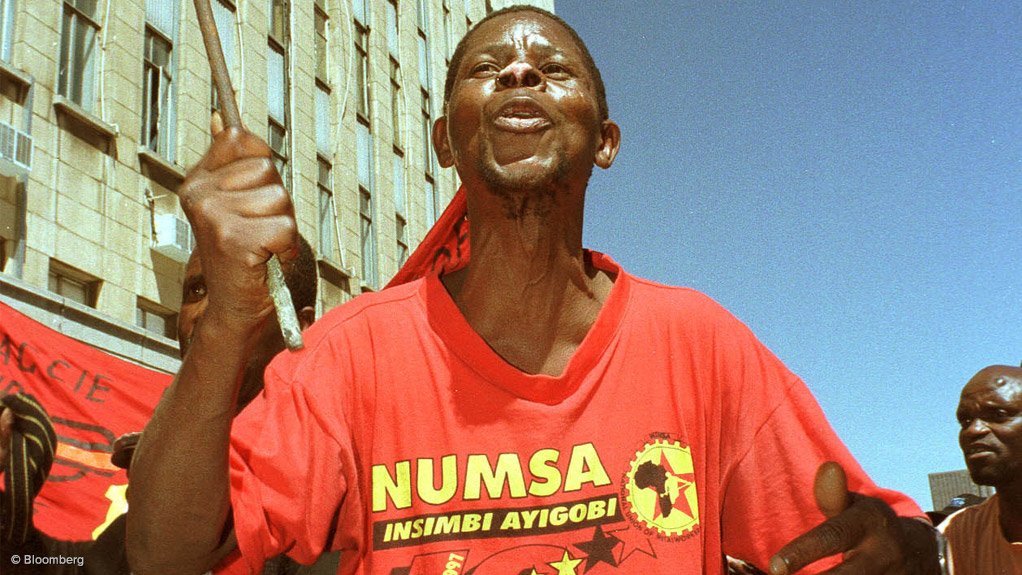

UNCERTAIN FUTURE The impending industrial action by metal workers, under the leadership of the NUMSA, has caused uncertainty within the fastener industry

The South African government’s Renewable Energy Independent Power Producer Procurement Programme (REIPPPP) is helping local manufacturers that supply the programme’s projects to manufacture quality products that meet international standards, states local fastener solutions provider SA Bolt Manufacturers.

SA Bolt Manufacturers financial manager Paul Cameron tells Engineering News that this is mostly because the foreign companies that run these projects expect nothing but the best from their suppliers.

As part of the REIPPPP’s mission to develop local businesses and create empowerment opportunities, the projects must procure most of their equipment from local manufacturers, to meet the local content requirement. Local content refers to the use of locally manufactured and procured products as well as local services companies.

Projects must also contribute to broad-based black economic empowerment, scarce skills transfer, empowerment of local communities and employment opportunity creation.

Cameron states that SA Bolt Manufacturers is a subsupplier to some companies that supply certain REIPPPP projects.

“The programme is a first world initiative in a third world country, where we have to deal with companies that expect first-class levels of quality services and products.

“We have had to improve our quality specifications and are now able to live up to First World companies’ expectations and deliver world-class products and services within a specified timeframe,” boasts Cameron.

He adds that to meet these standards, SA Bolt Manufacturers has had to enhance its skills and training courses as well as expand its staff complement. The company started focusing on manufacturing fastener solutions for the solar and wind renewable-energy sector over a year ago.

“Despite the bad economy, whereby the cost of manufacturing fasteners is on the increase, we have had to invest most of our resources in improving technical skills and ensuring that our products meet all the requirements,” he explains.

Branching into the renewable-energy sector has helped the company maintain its business and invest in training, at a time when local fastener manufacturers have been losing ground on market share owing to an increase in imports.

“Imported content, however, does not affect the renewable-energy sector as REIPPPP projects are required to use local content,” explains Cameron.

The first three rounds of the REIPPPP – spanning from 2011 to 2013 – have delivered 3 916 MW of electricity from 64 projects across the country. About R120.2-billion in investments has been the mobilised for the programme.

According to the World Bank Group’s ‘Public-private infrastructure advisory facility’ report titled ‘South Africa’s renewable energy IPP [independent power producer] procurement programme: Success factors and lessons’, in the first three rounds of the programme, the solar photovoltaic (PV), wind energy and concentrated solar power (CSP) technologies contributed to local empowerment in this way.

In terms of local content, the solar PV technology contributed 38.4% in the first round, 53.4% in the second round and 53.8% in the third round. In terms of job opportunities for locals during the construction phase, solar PV produced 2 381 jobs in the first round, 2 270 in the second round and 2 119 in the third round.

In the operation phase, the solar PV technology contributed 6 117 job opportunities for locals during the first round, 3 809 during the second round and 7 513 during the third round.

Wind energy technology contributed 27.4%, 48.1% and 46.9% towards local content in the first, second and third rounds respectively. In terms of job creation, round one contributed 1 810 jobs during the construction phase and 2 461 when in operation.

Round two contributed 1 787 jobs for locals during construction and 2 238 during operations, while round three contributed 2 612 local jobs during construction and 8 506 during operations.

The CSP technology contributed 34.6% of local content in the first round, 43.8% in the second round and 44.3% in the third round. During the first round, CSP contributed 1 883 job opportunities for South Africans during the construction phase and 1 382 opportunities during operations.

In the second round, the CSP technology created 1 164 jobs for locals during construction and 1 180 during operations, while round three created 3 082 jobs for locals during construction and 1 730 during operations.

Sector Uncertainty

SA Bolt Manufacturers MD Rodney Wooldridge tells Engineering News that the impending industrial action by metal workers, under the leadership of the National Union of Metalworkers of South Africa, has caused uncertainty within the fastener industry.

“We do not know when the strike will start but we do know that we cannot afford to tell our renewable-energy clients that we will not be able to supply goods because we have a strike on our hands.

“In anticipation of this we have been working ahead on our orders and have asked our customers to get their requirements to us as soon as possible so that we can start working on their orders right away,” Wooldridge explains.

He adds that only a margin of SA Bolt Manufacturers’ client base will be directly affected by the strike, while the remainder will only be affected by suppliers not delivering orders owing to the strike.

Cameron states that SA Bolt Manufacturers has just completed manufacturing a fastener solution for the foundation of wind turbines. “This is the first of its kind in the world and it took six months for us to develop,” he concludes.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation