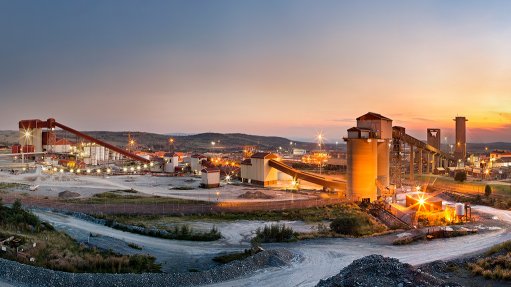

Kamoa-Kakula Phase 1 concentrator exceeds steady-state design throughput in Sept

The 3.8-million-tonne-a-year Phase 1 concentrator at Ivanhoe Mines' Kamoa-Kakula mine, in the Democratic Republic of Congo, milled 319 795 t of ore in September, exceeding the monthly design run rate of 316 667 t.

A total of 16 010 t of copper in concentrate were produced (filtered product) and a total of 16 503 t floated in the reporting month ended September 20 - Kamoa Copper's fourth full month of production - establishing a new monthly record and nearing the Phase 1 target output of 16 666 t a month, or 200 000 t/y.

The difference between filtered and floated copper is about 500 t in inventory in the concentrate thickener and the filter feed tank, Ivanhoe notes.

The average floated concentrate copper grade in September improved to 55.7%, up from about 48% in August.

A total of 46 764 t of copper in concentrate has been produced year-to-date for delivery to either the Lualaba copper smelter near Kolwezi, or to international markets.

Copper flotation recoveries improved to an average of 85.1% during September, up from an average of 83% during August. The Phase 1, steady-state-design copper recovery is about 86%, depending on ore feed grade.

A daily record copper recovery of 88.3% was achieved on September 12 and a daily floated copper production of 721 t was achieved on September 15.

Subsequent to the reporting period, a daily milling record of 12 596 t and a daily crushing record of 14 778 t were achieved on September 27.

"The Kamoa-Kakula team has worked tirelessly to bring the Phase 1 concentrator to steady-state performance. We are very pleased with the September results, where we exceeded steady-state design parameters for ore throughput and were close to achieving steady-state design copper recovery and monthly copper production," comments Kamoa Copper CEO Mark Farren.

He adds that a number of further adjustments are being made to the Phase 1 processing circuit to enable the concentrator to achieve better results in the next quarter.

Kamoa-Kakula is fast-tracking the commissioning of an additional concentrate filter, which has been installed alongside the Phase 1 filter, to be able to take advantage of copper feed grades and milling rates in excess of design parameters. The additional concentrate filter is expected to be fully operational in early October, enabling the Phase 1 concentrator to produce more copper than its design capacity of about 200 000 t/y.

"These adjustments, which also will be incorporated into the Phase 2 processing circuit, should position us to achieve 2021 copper production in the upper end of our previous guidance of 80 000 t to 95 000 t. This gives us the confidence to raise the range to 85 000 t to 95 000 t," says Farren.

Meanwhile, construction of the 3.8-million-tonne-a-year Phase 2 concentrator plant is also progressing well, with the overall project more than 50% complete. Engineering and procurement activities are effectively complete, with fabrication at 86% completion.

Civil construction works also are effectively complete, with the focus now on erection of structural steel and the installation of platework and equipment. A 400 t crane has arrived on site and has been used to lift the tailings thickener rake into position.

The crane also will shortly be used to install the ball mills, the ball mill shells, girth gear and ball mill ends, all of which are on site.

The bulk of the 2 193 t of structural steel and the 570 t of platework is on site and the bulk of the 18 644 m of piping is on its way to site.

The 6 km of tailings return water piping has been delivered to site and installation is nearing completion.

The Phase 2 concentrator remains on track for completion in the third quarter of 2022.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation