Jet Demolition has most technically-advanced fleet in Africa

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

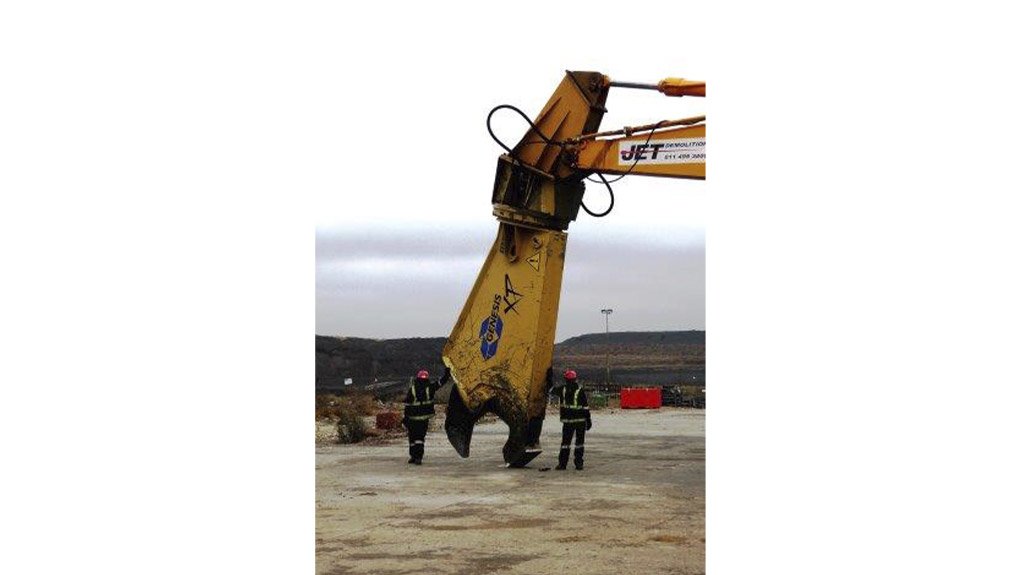

Jet Demolition has a fleet of 34 specialised demolition excavators, and 44 additional items of plant, ranging from skidsteer loaders to tractors, telescopic handlers, and articulated dumpers. It also has over 65 hydraulic attachments, and a range of mechanical attachments. This makes it not only the leading demolition specialist in Africa, but the most technically-advanced as well.

What makes Jet Demolition so unique is that the bulk of its equipment and attachments are unavailable locally. Although it uses reliable, well-known excavator brands, these are all adapted to suit the challenging and arduous demolition environment. “These modifications enable us to carry and operate with heavier attachments that are unavailable in South Africa,” Jet Demolition Operations Manager Willie Vermeulen explains.

Complex tools and attachments are imported specifically from abroad, while Jet Demolition has an in-house R&D capability to develop and manufacture simpler attachments and tools locally. Vermeulen reveals that the material cost alone is often more than the attachment value if it were to be purchased outright. However, this is due to the attachments being designed and built to long out-last those available commercially.

Jet Demolition has also established relationships with original equipment manufacturers (OEMs) and engineering firms over the years, which ensures that the specific tools it requires are manufactured to exacting quality and precision standards. In addition, its relationships with international demolition professionals, as well as a keen interest in mechanical engineering, gives it the capability to modify equipment suited specifically to its requirements.

Generally it is very uncommon for any equipment or attachments to be only for a once-off application. Before investing resources into any tool or attachment, Jet Demolition always analyses ways that it can be incorporated into different projects. “While we are able to safely execute the same operation using a different method, a decision to purchase or manufacture a specific tool to perform that function is generally motivated by the safer, quicker, and more reliable operating performance provided,” Vermeulen stresses.

Jet Demolition has its own fully-equipped on-site workshop at its Roodepoort premises. General services are carried out on-site by trained and qualified mechanics. While most contractors tend to run their machines into the tens of thousands of hours before considering replacement, the demolition specialist replaces its key machines at about 6 000 hours on average.

“This is exceptionally uncommon in the heavy equipment market. We need to be able to ensure that our machines are ready to work under any and all circumstances, and simply cannot afford to have an unforeseen breakdown during critical activities. For this reason. we keep our fleet relatively young, and make a considerable investment in our fleet,” Vermeulen highlights.

In addition to basic operator training and certification, on-site experience and mentoring is critical. “Our operators generally carry the same accreditations as earthworks contractors, but their expertise as specialised demolition operators sets them apart. It is similar to the crane industry in that operators may have a licence, but their experience, confidence, and performance determines the extent of their development and growth,” Vermeulen adds.

Commenting on the latest equipment trends and developments, Vermeulen points out that mechanisation is an ongoing objective of many large demolition firms. “We have also noted a trend in using digital advances, including sensors, anti-collision devices, and complicated live-feed camera systems that are able to further advance safety in the demolition industry,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation