Innovative Vertical Gravity Samplers

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Designed And Manufactured By Edart

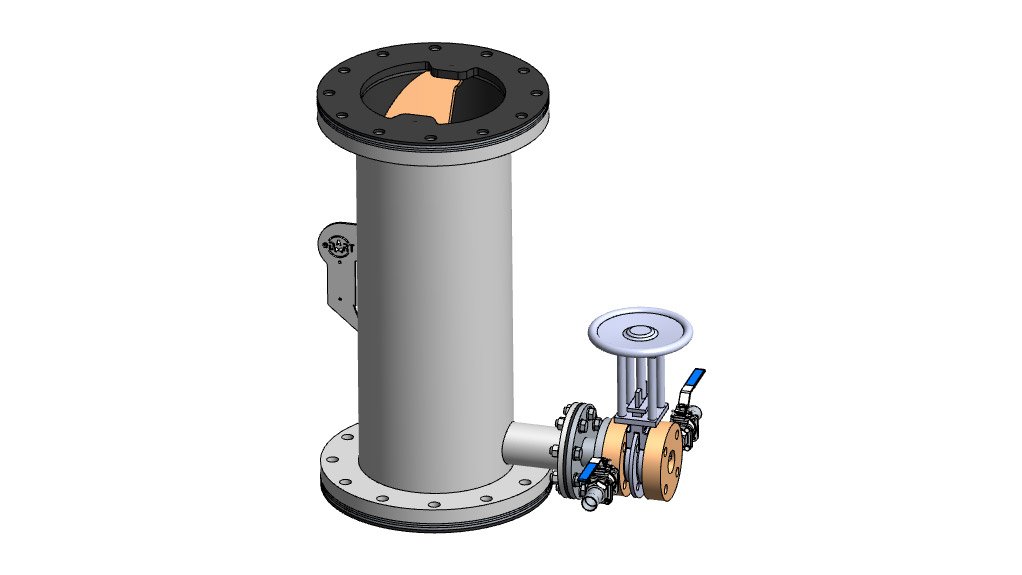

To meet the requirement of an international customer, eDART Slurry Valves, a leading South African valve manufacturer, successfully designed, tested and manufactured a Vertical Gravity Sampler (VGSA) for application within the minerals processing sector.

Duane le Roux, Product Manager – Samplers, at the eDart Group said “We received a request from one of our global customers to develop a solution that could enable them to obtain a credible sampling of their gravity fed downward flowing process line. A VGSA is only selected if there is no horizontally sloped gravity fed process line available in which to install a normal gravity sampler assembly (GSA)”.

“After site assessment, it was a concern that sampling from this line ensured that the cutter received enough sample and moreover that this sample was representative. We ran various computerised design configurations and simulations in order to meet the customer criteria and this led to the development of a totally South African designed and manufactured VGSA – the first in the country” he said.

The VGSA has a cylindrical shape and is relatively compact compared to the average size of mining equipment. It is easily installed, requiring only minor alterations to the pipeline to which it is to be installed. The body of the sampler is designed to be replaced once worn. The sampler is made from various erosion resistant materials such as rubber and polyurethane linings, stainless steel and tungsten carbide coated steel.

The specifically zig zag designed baffle plates within the VGSA direct slurry in a non-gravity process line closer together. Eventually a constant stream of slurry is formed. This slurry stream is then directed straight into a cutter, which has been designed and tested using computational fluid dynamics (CFD) software.

The VGSA is supplied in industry standard pipe sizes (diameter), in order to fit into the process pipelines. For standard models the height of the sampler would be the function of the diameter. This would be determined by utilising simulation software which would consider the mine’s mass balance of slurry.

eDART has supplied this type of sampler where there were space restraints within the plant’s layout. In this instance eDART supplied a VGSA with a custom height to fit the customer’s specification, which was verified using computational analysis.

“We believe that our VGSA is a solution in mines where there is no alternative place to offer a traditional eDART sampler product, therefore it is a natural extension of our product offering” commented le Roux.

“Industry is realising the power and convenience of process control samplers versus met accounting samplers, and process control samplers are being considered as a vital tool to mining operations”. Additionally, le Roux said “Sampling from a downward gravity process line is difficult by nature. Results have indicated that previous solutions that were built to try and sample from a gravity fed downward flowing process were ineffective and not representative.

We have countered this by using good computational simulation which has given us with excellent results and client feedback has supported these findings” said le Roux.

“It is important for us to find effective solutions that satisfy our customer’s specific requirements, even if for an uncommon and non-standard application. We credit ourselves for having the design and knowledge skills to offer a reliable solution to any sampling need. At the end of the day it also expands our sampler offering” concluded le Roux.

eDART are specialists in the design and manufacture of samplers and slurry equipment and offer external and internal dual/single dart valves, as well as pinch, dosing and slurry valves; pneumatic actuators, instrumentation, samplers, flow analysis technology and related accessories.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation