Automation system offers brewery real-time processing visibility

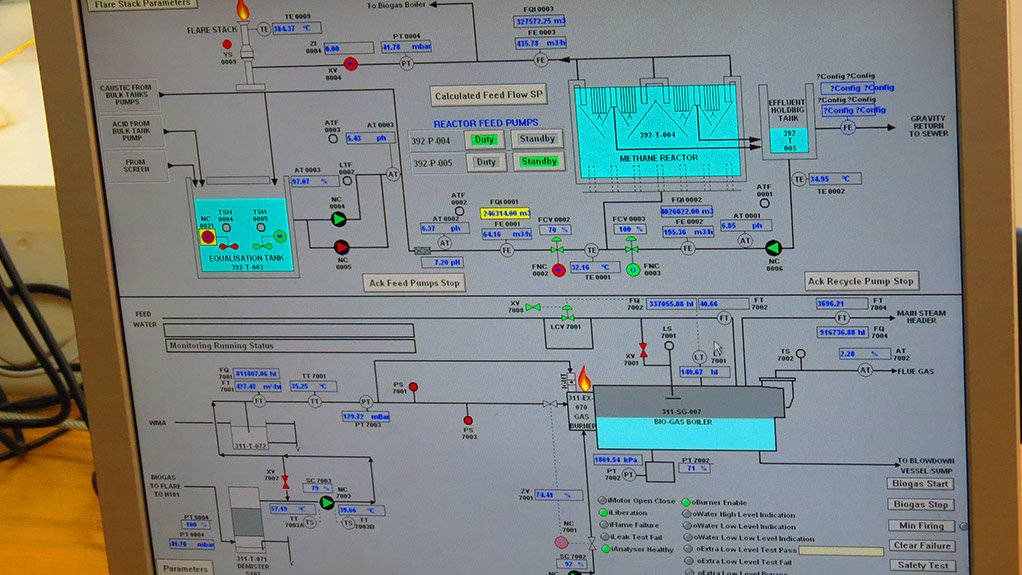

WONDERWARE INTERFACE The Wonderware system has also been programmed with integrated maintenance, sampling and cleaning triggers

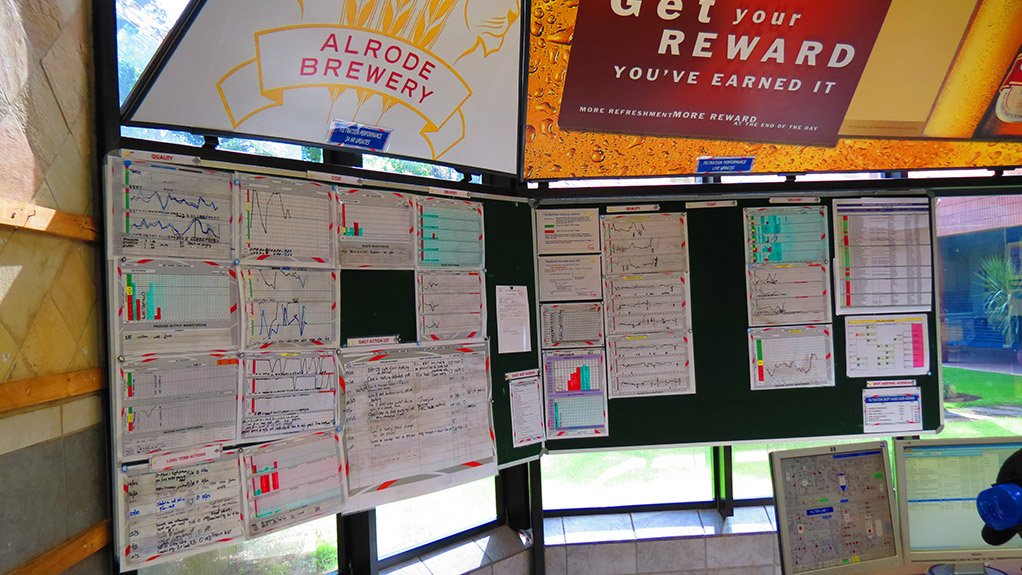

CONTROL ROOM SAB wants operators to take ownership of their processes while maintaining quality oversight

Beer giant SAB uses a flexible industrial control system at its Alrode Brewery, in Alberton, to ensure it maintains the quality of the different brands, despite differences in their ingredients, brewing and maturation, says SAB Alrode Brewery systems manager Grant Wolff.

SAB has made significant commitments to using water and energy efficiently in its brewing operations. It is able to meet and is starting to exceed its environmental impact reduction targets through close monitoring, highly skilled teams and active performance management, he says.

The Alrode Brewery is the largest in South Africa capable of producing 8.8-million hectolitres a year of Black Label, Castle, Castle Lite, Castle Milk Stout and Hansa beers and is the only brewery in South Africa to brew Millers Genuine Draft (MGD) beer.

The brewery uses industrial automation company Invensys’ Wonderware system that monitors 75 000 tags and measures 58 000 points in the brewery every millisecond, providing a highly detailed picture of all aspects of brewing, cleaning, maintenance and bottling across all the processes.

The integrated system, which uses the real-time inputs to determine thousands of different and inter-dependent key performance indicators for all types of employees and functions, enables SAB to monitor the trends throughout the brewery with automatic alerts and work orders sent to employees and contractors, notes Wolff.

The Wonderware system has also been programmed with integrated maintenance, sampling and cleaning triggers.

Reports are automatically generated to enable the brewers, engineers, executives and accountants at the brewery to have real-time production data to achieve their production targets while meeting low water- and energy-use targets. These reports are securely stored to serve as data for investigations and audits.

“Future plans include beginning a virtualisation project at Alrode Brewery next month, which will enable us to reduce our server footprint and use our existing hardware for redundancy and fail-safe measures,” he says.

Visual Management is a key trend for SAB because it enables the company to empower individual employees with data and tools to monitor and improve their performances, while key performance indicators are automatically adjusted as better performance is realised.

“We want our operators to take ownership of their processes while maintaining quality oversight. Future plans envisage providing operators and consultants with personal digital assistant devices to enable them to do fault finding as soon as a fault is detected in the system.”

“These capabilities will be in parallel with our goal to simplify users’ interfaces and rather let the system highlight only parts of the process that are outside specifications, enabling operators to focus on process efficiency and optimisation,” concludes Wolff.

Alrode completes 24 brews a day in its three brew houses. There are 96 fermentation vessels and varying maturation times for the different beers. Five packaging lines, the fastest being capable of handling 60 000 bottles an hour, fills, seals, packages and places 750 mℓ to 330 mℓ bottles on pallets, which are imme-diately loaded onto trucks waiting at the ends of the lines. Each of the bright beer tanks prior to bottling holds enough beer to fill three large swimming pools.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation