Indian dam project demonstrates Vesconite creep, abrasion resistance

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

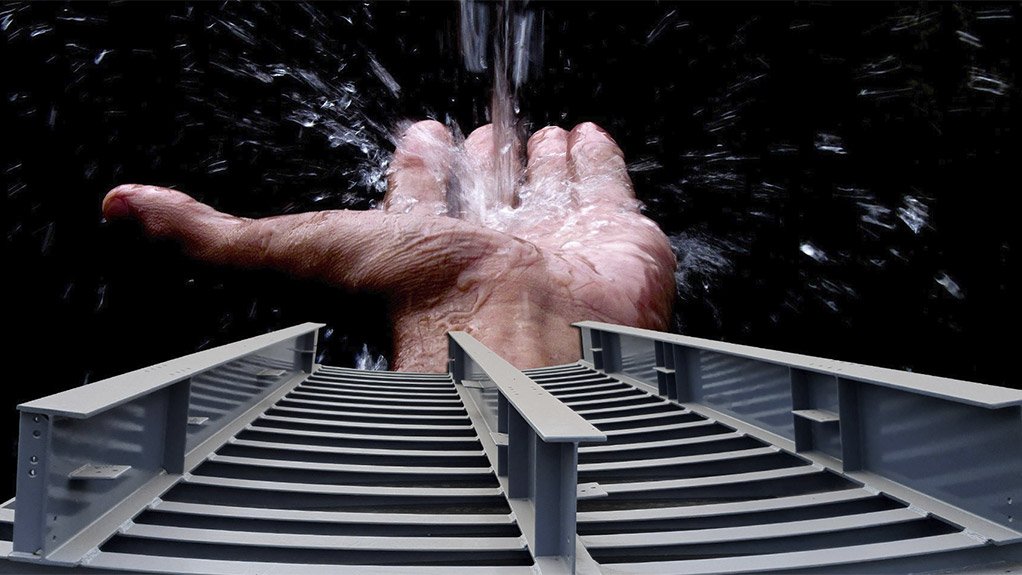

Indian hydro-electric projects offer unique challenges: they are exposed to monsoon floods for a few months of the year and then a dry spell for the rest of the year.

After being dormant for long periods, bearings associated with these projects have to cope with a deluge of water containing debris from the floods.

These conditions led one Indian company that does maintenance of hydro-electric dams and, specifically, the sluice gates and other structures associated with the dam walls, to approach Vesconite Bearings for a solution for the trunnion bearings on one of its project’s tainter gates. These gates are used to release or stop water on hydro-electric dams.

The main problem that the maintenance company had experienced prior to using

Vesconite Hilube trunnion bearings was that monsoon-related debris and silt were getting stuck in the bearings and damaging them.

Vesconite Hilube bearings were then installed in June 2022, immediately preceding the anticipated monsoon rains.

Since it is a harder material than many of the competing brands, it is good at handling abrasives. This is because it does not provide a yielding surface for abrasive material to indent in and, because the harder material is unyielding, silt particles will generally flush through.

In addition, because Vesconite Hilube bearing material does not swell even in submerged conditions, tighter tolerances and clearances are possible. This translates into a smaller gap for debris, including small sticks and bark, to get stuck in and damage the bearing.

Vesconite Bearings renewable energy application developer Petrus Fourie notes that he recommended clearances in line with Vesconite Bearings’ online “Design a Bearing” calculator and believes that Vesconite Bearings’ smaller recommended tolerances and clearances assisted in the success of the trunnion bearings.

The client informed that the dam gates were operating well in the middle of the monsoon season, and again confirmed in March 2023, following the monsoon season, that the bearings were working well.

Other than the wear-resistant properties of Vesconite Hilube, Fourie notes that Indian hydro-electric projects are also a unique environment in which to test a material’s creep resistance ⎻ its likelihood of deforming under load.

In this respect, the Vesconite Hilube trunnion bearings also performed well.

Indian dams sit closed for almost 9 months of the year during the dry season when it is imperative for them to hold back the water in the dam.

During this time, bearings are exposed to a high load that can result in creep and there is a tendency for the bearing to deform and become oval on the inside.

This results in the gate being unable to open since the shaft cannot turn since the irregularly-shaped bearings cause jams.

While this is unlikely to be a problem in Europe, where dams open and close all the time due to the on-going rainfall, this is a problem in countries like India with a lengthy dry season and particularly where other creep-prone plastic bearings are in place, or bronze, which is soft and prone to creep and can experience galvanic corrosion resulting in seizures.

However, Vesconite Hilube trunnion bearings demonstrated their ability to keep their shape and the gates of the hydro project were able to open and close since the bearing hole remained round and could rotate around the shaft.

“If they can work in India, it’s pretty safe to say that the bearings are fairly creep resistant because of the way Indian companies operate their dams,” Fourie enthuses.

The Indian maintenance client seems similarly enthusiastic and has sent through additional enquiries.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation