HowardPhillips puts quality and service back into the powder coating industry

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The name HowardPhillips represents a team of specialists with a shared goal of providing customers with world-class quality aluminium powder coating solutions.

The company is spearheaded by powder coating industry guru Barney Phillips who, when establishing HowardPhillips (Pty) Ltd. in August 2016, assembled a team of nine professionals who have a combined experience of over 60 years in the powder coating industry. “We specialise in the powder coating of a wide range of aluminium products including extrusions as well as fabricated louvres and frames to prevent corrosion and increase the life span of the products.”

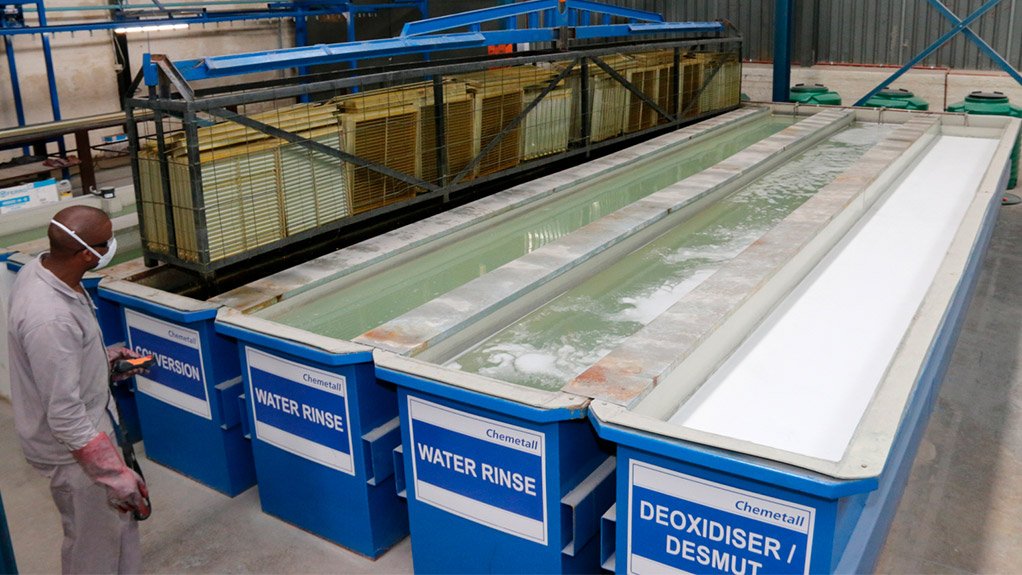

“We have made a significant investment into a state-of-the-art plant that is fitted out with brand new equipment that includes six 8m long washing tasks, a 20m long tunnel oven, powder coating units with three spray guns as well as a moisture-free conveyor with after-filters. This gives us the capacity to handle from very small to extremely large jobs.”

The first step in the powder coating process is extremely important as all precautions must be taken to prevent contamination of the untreated aluminium products as well as the dipping tanks.

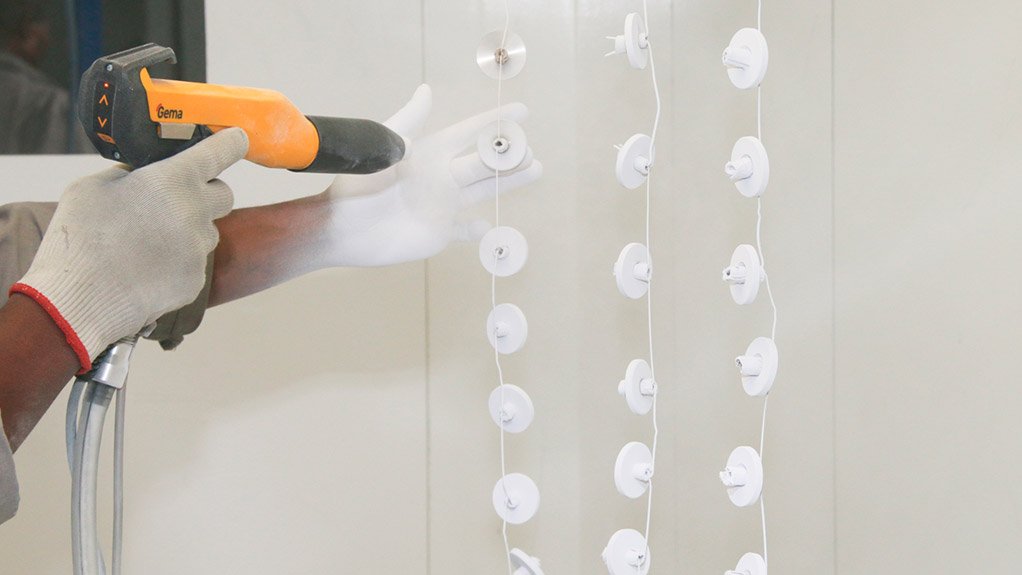

Once the chemicals have prepared the aluminium surface in order to accept the powder coating, the products are placed on a conveyor belt and moved along for powder coating to the customers’ colour specifications. The company is geared to provide customers with their individual colours of choice and Phillips adds that every colour is coded to ensure consistency. “So 20 years down the line we are able to precisely match a colour.” The powder coated aluminium is baked at 180°C for 20 minutes in the tunnel oven. Once cooled, the product is wrapped, ready for collection.

HowardPhillips’ scope of work also extends to the powder coating of steel products. “We outsource the sand blasting process to a reputable partner to prepare the steel product for powder coating.”

Phillips explains why he and his team regard top-notch service as fundamental to the success of the business. “Powder coating is the final step or the end of the manufacturing process in the total supply chain. All that remains is cutting to length and/or installation. So the customer does not need any hassles at this last stage when the end is in sight.”

“We also understand that time is money for our customers and that they are not the end-user of the powder coating products. So it is our responsibility to ensure that our customers are able to meet their customers’ specifications and deadlines.

We are system orientated and by keeping the process simple we are able to tick all the boxes for our customers by supplying superior quality powder coating in the specified colours, on time - full stop - no commas or semi-colons. When our customers cut-to- length they can rest assured in the knowledge that there will be no chipping, cracking, peeling or lifting.”

The personnel are seen as HowardPhillips’ most valuable assets. The responsibility to streamline all the processes rests on the shoulders of Moses Mpofu who boasts more than 20 years’ experience in the art of powder coating. In acknowledgment of his commitment and work excellence Moses was recently appointed as Director of Operations. “I am very happy to be part of the setting up and running of HowardPhillips,” comments Moses. “It has been a wish of mine for a very long time. We are here to ensure that only the very best treatment is passed on to our customers and business partners and our motto of Quality – Right first time prevails.”

Phillips also highlights the importance of establishing strong customer relationships. This can only be achieved by earning the customer’s trust through consistently delivering the best powder coating experience possible,” concludes Phillips.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation