How Long Does It Take To Change The Sleeve In A 350nb Pn25 Pinch Valve? - One Hour Twenty Minutes

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The standard practice for replacing a sleeve in any pinch valve is to remove the valve from the line which requires the use of a crane for all but the smallest valves. The valve is then stripped – the sleeve replaced – and the valve rebuilt. It is then reinstalled in the line – a process that can take several hours at best requiring the attention of several fitters and millwrights.

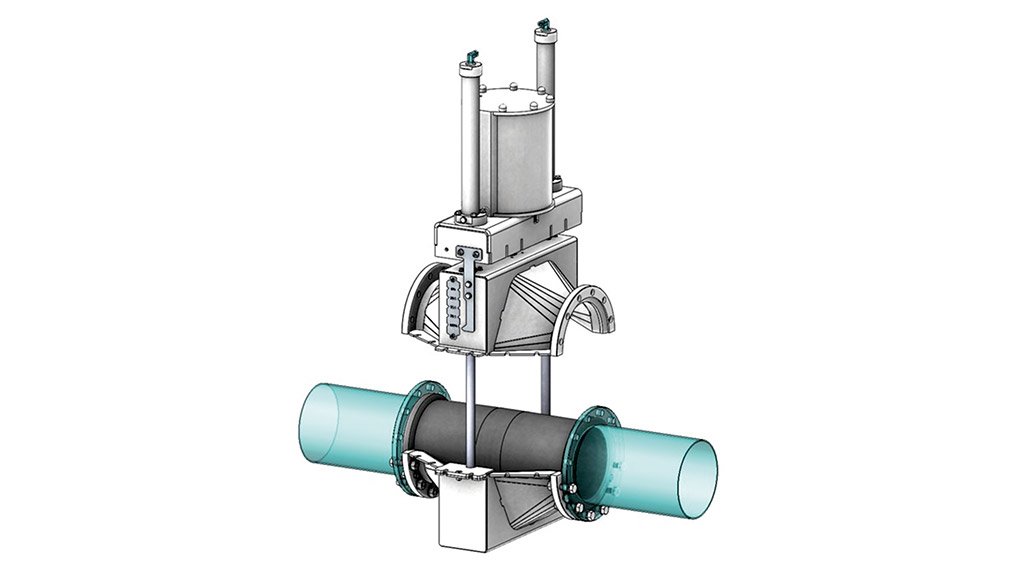

With the patented Red Roc Hi-Lift feature the valve remains in the line and the sleeve can be replaced in a much shorter time with only two fitters.

On 15 September 2017 at a nickel mine in Mpumalanga a Red Roc valve sleeve was changed in 80 minutes and reduced the plant downtime by at least ten hours.

“The process is simple and only involves removing the bolts holding the top half of the body in the line and slackening the ones in the bottom half. Jacking bolts on the valve flanges spread the valve flanges from the pipe flanges loosening the sleeve, so that it can be removed in line.

The quick release clamps holding the two halves together are removed. The top half is then raised using the two hydraulic cylinders mounted on the bridge and operated by a hand pump. In the raised position the old sleeve can be lifted out and the new one fitted in position.

The process is then reversed with the body being allowed to drop by releasing the oil in the cylinders back to the reservoir – the clamps are refitted and line bolting replaced” said Gregor Hopton, Afrivalve’s Group Marketing Manager.

The Red Roc Hi-Lift pinch valves are manufactured by Afrivalve, a division of eDART Slurry Valves at eDART Slurry Valve’s facilities in Jet Park, Gauteng. The range includes sizes from DN150-DN600. Larger sizes are available upon request.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation