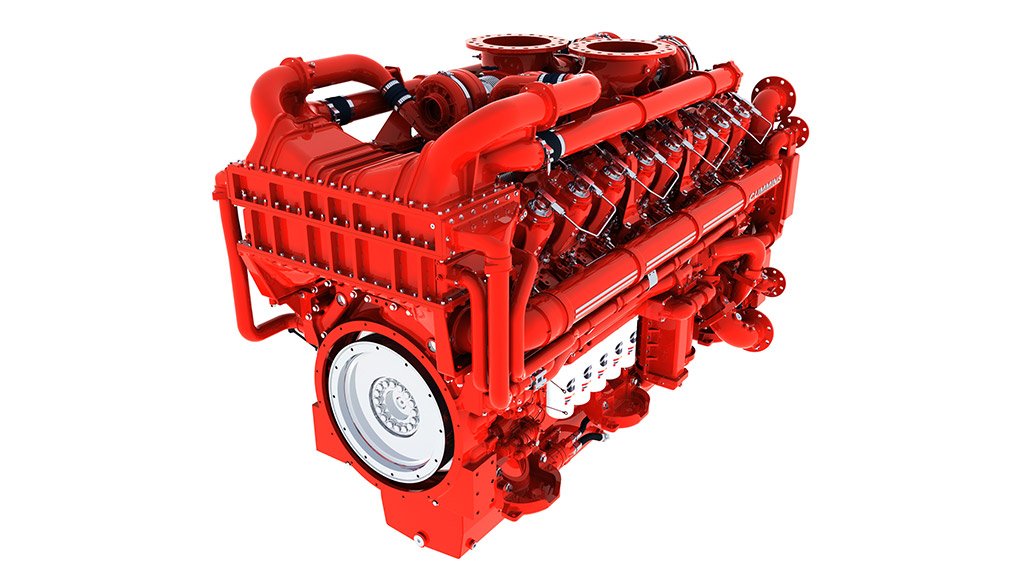

High-horsepower locomotive engine destined for SA

HIGH HORSEPOWER The Cummins QSK95 tier 3 engine produces 3 600 hp at only 1 800 rpm

US-based engine manufacturer Cummins’ high-horsepower diesel engine, the QSK95 Tier 3, will be launched in South Africa in either late 2016, or early 2017.

Cummins South Africa, represented through a local head office in Woodmead, in Johannesburg, has several service centres in the country that include a high-horsepower rebuild centre in Johannesburg, which is tasked with maintaining engines such as the QSK95.

Although the Tier 4 variant of Cummins’ QSK95 was launched in mid-2015, in the US, the Tier 3 variant is destined for deliveries to potential locomotive clients in South Africa, who are currently allowed to place orders for the new engine.

The Tier 3 variant produces a maximum of 3 600 hp, which is rated at an engine speed of 1 800 rpm. This power stems from the significant size of its diesel engine that features V16 cylinder configuration, the latest-generation modular common-rail fuel injection, 95 ℓ displacement and single-stage quad turbochargers.

A two-stage after-cooling radiator reduces the radiator size of a conventional single-stage radiator, thereby also reducing overall engine package requirements.

All these features assist the QSK95 in having a smaller footprint and less noise, compared with medium-speed diesel engines, which are traditionally used in locomotives.

Further, on the latest Tier 4 variant of the QSK95, an integrated selective catalytic reduction exhaust after-treatment system enables the engine to achieve the ultralow emissions stipulated by the US Environmental Protection Agency’s Tier 4 emissions requirements.

Several factors ensure engine reliability. These include a midstop engine liner, which provides engine coolant at high locations on the engine block, thereby keeping the engine cooler during combustion processes; enhanced bore and stroke dimensions, which result in lower piston speeds; and less heat that results in extended engine life spans.

A central overhead camshaft reduces the number of parts required, while a prelubrication pump enhances durability by ensuring adequate lubrication during the starting of the engine. The engine block also features a bedplate to add robustness, and a deep skirt for improved serviceability.

Cummins US says the company’s strong presence in mining and marine markets in Africa is supported by an extensive service network that ensures that Cummins can support the South African rail industry.

Further, distribution personnel from Cummins partner with personnel at its rebuild centre as well as customers to ensure clients receive enhanced productivity and lifetime value from high-horsepower Cummins engines.

Meanwhile, the first Cummins QSK95 Tier 4 variant, which was built to locomotive specification, was shipped to locomotive manufacturer Siemens’ manufacturing facility in Sacramento, California, in the US, in late September 2015.

The Tier 4 engine, rated to 4 400 hp, will be installed in a diesel-electric passenger locomotive, the Charger, which is set to be put into service by the departments of transportation in the US states of Illinois, California, Michigan, Missouri and Washington. This will form part of a 35-unit order of Chargers.

The Charger will also power the trainsets for All Aboard Florida – a passenger rail project connecting Miami to Fort Lauderdale, West Palm Beach and Orlando, in Florida.

Cummins US state that, for years, the company’s high-horsepower engines have been designed to operate in the harshest environments such as mining and oil and gas applications.

The company notes that understanding these types of operating conditions and requirements enables it to meet the requirements of rail installations. Owing to robust design, Cummins’ engines deliver industry reliability and durability, resulting in low total cost of ownership for customers.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation