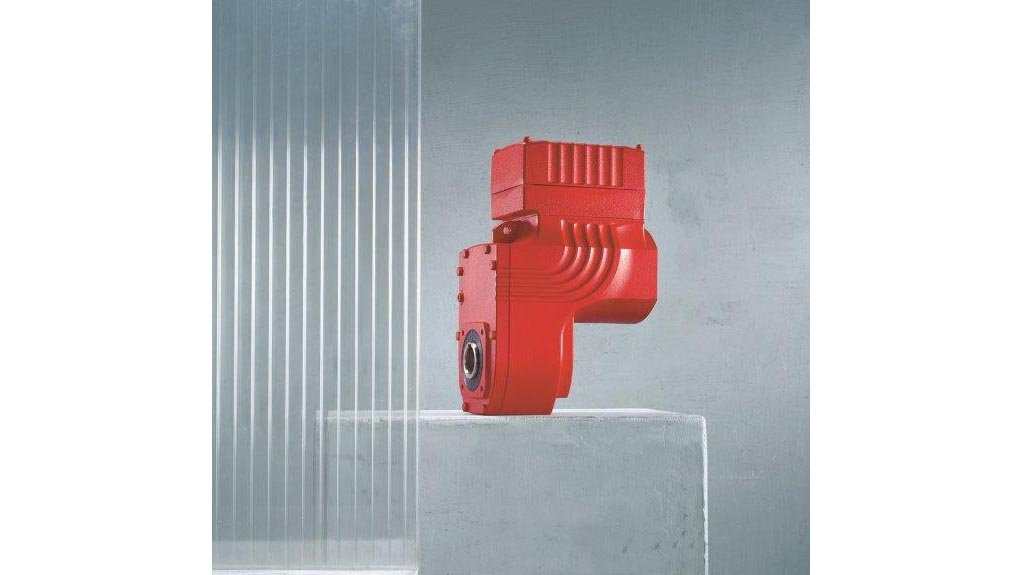

Glass manufacturer standardises on MOVIGEAR® units for new bottling line

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

SEW-EURODRIVE South Africa has delivered 67 MOVIGEAR® mechatronic integrated drive units to a major glass-manufacturing facility in the Western Cape in a record turnaround time of six weeks. Components were sourced from Germany, while the units were assembled in Cape Town.

The order for the Western Cape facility follows on from work that SEW-EURODRIVE South Africa undertook for its customer in Gauteng about six years ago. All the planning for the latest expansion was carried out at the customer’s head office in Wadeville, Gauteng, where conveyor systems for its bottling lines are all designed in-house, SEW-EURODRIVE South Africa Sales Engineer Sean Tibbott explains.

The fact that the original bottling line has been running successfully on MOVIGEAR® units to date means that the technology is tried-and-tested. “That essentially paved the way for the Western Cape expansion, in keeping with the general industry trend of energy-efficiency and cost-saving,” Tibbott highlights. The project is a good benchmark for mechatronics in general, and MOVIGEAR® in particular.

“Industry has tended to shy away from this technology in the past, mainly due to a lack of understanding on its part,” SEW-EURODRIVE South Africa Regional Sales Manager Clive O’Reilly reveals. “However, major customers such as this have not only assisted us in making inroads in important markets such as food and beverage, but have raised the profile of mechatronics in general.”

A challenge for SEW-EURODRIVE South Africa is to educate the engineering community about the benefits of mechatronics, and in particular its contribution to the lowest total cost of ownership. “Our practical approach to the issue of raising awareness and providing fact-based figures is to install a MOVIGEAR® unit for a trial period, and then to measure and compare the power consumption. The energy saving is so dramatic that it has a significant impact on reducing the initial upfront investment in the technology.”

SEW-EURODRIVE South Africa is fast establishing itself as a mechatronics leader in the country due to its local manufacturing capability and its technical support. “If you look at our competitors, none of their units are even repaired locally, whereas we not only have the spares stockholding and necessary expertise, but we offer a 24/7 aftermarket service as well.”

Another major factor giving MOVIGEAR® the leading edge in the local market is that it is available in four variants, increasing its adaptability to different plant layouts. “This extends our flexibility considerably in being able to respond to customers’ diverse requirements and applications,” Tibbott adds. In addition, the MOVIGEAR® units are ideal for corrosive environments or those where strict hygiene standards have to be complied with.

“Mechatronics is an ideal technology for African operating conditions, due to the fact that it integrates mechanics and electronics, unlike the more traditional splittable units. Such integration means there is a minimal margin for error when it comes to installation and commissioning, while the units are also virtually maintenance-free, which reduces downtime and labour costs,” Tibbott concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation