Geothermal systems installed at Steyn City development

PALAZZO STEYN Environmental Drilling & Remediation Services in July completed the installation of 18 borehole closed-loop geothermal heat pump systems at the private residence of South African billionaire Douw Steyn’s Palazzo Steyn

UNDERSTANDING GEOTHERMAL TECHNOLOGY In winter, the ground is warmer than the air, which means that cold water pumped through the pipes returns at a warmer temperature, and does the opposite in summer

SAVING ON COSTS Building owners can save about 80% on their yearly heating and cooling costs using geothermal heat pumps

Geothermal technologies are increasingly becoming a global means of effectively heating and cooling industrial and residential buildings, owing to rising electricity costs and increasing levels of consumer environmental awareness, says local environmental contracting company Environmental Drilling & Remediation Services (EDRS) owner Derek Whitfield.

He tells Engineering News that, in July, the company completed the installation of 18 borehole closed-loop geothermal heat pump systems at the private residence of South African billionaire Douw Steyn’s Palazzo Steyn, in the 900 ha Steyn City parkland estate, in Johannesburg North, along the Jukskei river.

EDRS also installed a geothermal heat system worth about R26.6-million at the environment-friendly Hotel Verde, in Cape Town, Engineering News reported in February.

Understanding Geothermal Technology

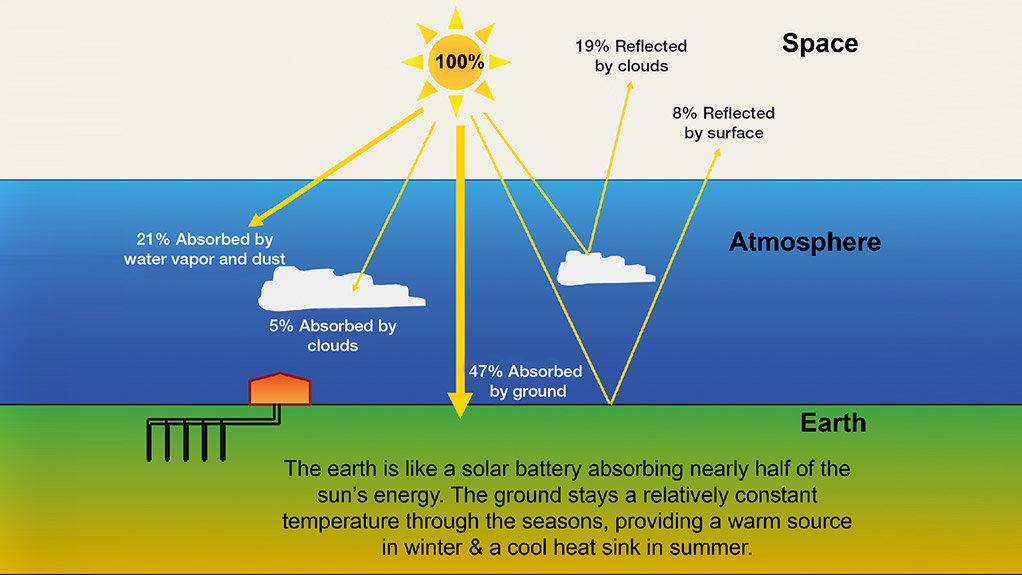

Whitfield explains that, in winter, the ground is warmer than the air and in summer the ground is cooler than the air, which means it can be efficiently used all year round. Water is pumped through the buried loop field, and returns at a warmer temperature in winter and at a cooler temperature in summer than the temperature air.

He points out that geothermal technologies were developed mainly for northern hemisphere countries with extreme winters, such as the US, Canada and Europe but are starting to become popular in Australia owing to their energy efficiencies.

Geothermal technology has not been used as widely in the southern hemisphere, owing to the milder climates and access to such technologies being less prevalent than in the northern hemisphere.

Whitfield explains that, in South Africa, heat pumps are traditionally air-to-water sourced systems, unlike geothermal heat pumps, which are water-water sourced pumping systems.

According to the US Department of Energy’s website, about 50 000 geothermal heat pumps are installed in the US each year.

Whitfield says geothermal heat pumps use the constant temperature of the earth as the exchange medium, instead of air temperature.

“Relative to air-sourced heat pumps, they are quieter, last longer and need little maintenance,” he adds.

Moreover, he notes that a hybrid heat pump combines an air-heat exchanger with geothermal heat pumps, as this technology allows for removal of excessive heat from the loopfield.

Although the installation price of a geothermal system can be several times that of an air-source system of the same heating and cooling capacity, he stresses that the additional costs can be recouped in energy savings in five to ten years. Life cycle costs are definitely less than a conventional heating, ventilation, and air-conditioning system.

There are four basic types of ground-loop geothermal systems. Three of these geothermal heat pumps systems – the horizontal, vertical and pond/lake systems – are closed-loop systems, while the fourth system is an open-loop system.

Whitfield notes that the best option depends on the climate, soil conditions, available land, and local site conditions.

Closed-Loop Systems

Whitfield explains that most closed-loop geothermal heat pumps circulate through a closed-loop piping system, which is made of high-density polyethylene (HDPE) plastic tubing and placed underground or submerged in water.

“A heat exchanger then transfers heat between the refrigerant in the heat pump and the water in the closed loop,” says Whitfield.

Horizontal System

Whitfield notes that horizontal installations are generally the most cost-effective for residential installations, particularly for new construction where sufficient land is available. The installations require trenches of between 3 m and 5 m deep.

“The ‘slinky’ method of looping pipe allows more pipe in a shorter trench, cuts down on installation costs and makes horizontal installation possible in areas where it is usually not possible using conventional horizontal applications.”

Vertical System

Whitfield notes that commercial buildings and residences often use vertical systems, as the land area required for horizontal loops would be prohibitive.

He adds that vertical loops are used where the soil is too shallow for trenching, as it reduces interference to existing landscaping.

“For a vertical system, holes of about 165 mm in diameter are drilled, about 10 m apart and 60 m to 120 m deep. Two pipes are then placed in these holes and are connected at the bottom of the hole with a U-bend to form a loop,” Whitfield states.

He notes that one borehole of about 120 m generates between 3.5 kW to 7 kW of heating/cooling.

Whitfield explains that the vertical loops are sealed with a bentonite grout to prevent contamination of the surrounding groundwater or aquifers and are, in turn, connected with horizontal pipes in trenches, which are then connected to the heat pump in the building.

Pond/Lake System

Whitfield says the lowest cost option may depend on a site having an adequate water body, as a supply-line pipe is run underground from the building to the water and coiled into circles at least 2.5 m under the surface.

“The coils should be placed in a water source only if it meets minimum volume, depth and quality criteria,” he warns.

Typically, the geothermal heat pump pond-loop configuration requires at least a 1 000 m2 to 2 000 m2 pond or lake to be used, which is at least 2.5 m to 4 m deep.

He stresses that the loop must be sunk to the bottom of the pond.

Open-Loop System

Whitfield says this system uses a well or a body of water as a heat-exchange fluid, which circulates directly through the geothermal heat pump system.

“Once it has circulated through the system, the water returns to the ground through a well, a recharge well or surface discharge. This option is practical only where there is an adequate supply of relatively clean water and all local codes and regulations regarding groundwater discharge are met,” he explains.

Whitfield adds that the open-loop system has limited potential in South Africa, owing to its lack of large bodies of waters and primary aquifers.

Hydronic-Loop System

This distribution system provides heating, with warm water distributed in a room’s floor tubing. The piping thermally activates the concrete slabs and creates a room zone temperature control for heating and cooling purposes.

EDRS installed this system in March at a 140 m2 flat in Morningside, Johannesburg.

Benefits of Geothermal Heat Pumps

Whitfield says that building owners can save about 80% on their yearly heating and cooling costs using geothermal heat pumps. The operational variable-speed blower motor can run continuously for the cost of about 50c/d.

The source of the heating is free – the sun’s rays are absorbed into the ground – and renewable. The system is completely environment-friendly and functions effectively, even in the harshest of climates.

A 4 046.9 m² lot possess about two-million kilowatt-hours a year of geothermal energy, while the average home only requires about 12 000 kWh/y to have adequate heating and cooling.

The domestic hot-water geothermal heat pump system’s desuperheater generates hot water whenever the compressor is in operation to heat or cool the home.

“Instead of pumping the excess heat produced back into the ground, it can be transferred to a geyser, free of charge, as a by-product of the cooling system by extracting heat from a building,” Whitfield asserts.

He says replacing a gas furnace with a geothermal system in an average home reduces greenhouse-gas emissions by about the same amount as when two motor vehicles are removed from the roads.

The geothermal heat pump system consists mainly of HDPE piping, which is environment-friendly, as it is 100% recyclable. Additionally, recycled HDPE creates no harmful emissions during its production or during its use by the consumer.

Whitfield notes that HDPE piping does not leak toxic chemicals into the soil or water.

He points out that HDPE piping has a 50-year manufacturer warranty and can last up to 200 years.

Whitfield says the required input energy to deliver 10 kWh of heat to a home using resistance heat is 30 kWh and about 70% of the input energy is lost during the generation and transmission process of a typical coal-fired power plant.

The resistance heat will deliver a 1:1 ratio of energy supplied to energy delivered.

“Geothermal heat pumps require only 9 kWh from the source to provide 10 kWh for the building, since the pumps can provide a coefficient of performance of 3.7 kW. Therefore, 3.7 kW of cooling will be produced for every 1 kW of electricity used, indicating that geothermal technologies have significantly high operating efficiencies,” he concludes.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation