Gear business driven by sustainability

SEW-EURODRIVE has developed a CO2 reduced lubricant for its gear units

The carbon footprint of GearFluid has been improved by 84% compared to petroleum based polyglycol base oils

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Pinpointing climate change as possibly the most serious challenge humankind has ever had to tackle, SEW-EURODRIVE has for many years pursued a sustainability agenda that is applied across every aspect of its business.

According to SEW-EURODRIVE Managing Partner Jürgen Blickle, the company recognises that the number and scale of natural disasters is growing at an alarming rate – threatening people all round the world.

“This means every one of us has a responsibility to do what we can to slow down and stop this process, and this is particularly true for industry,” says Blickle. He points out that sustainability is nothing new for SEW‑EURODRIVE, which has long since seen recycling as an essential step in achieving a sustainable circular economy. The company has also championed renewable and efficient energy sources, and maximised the energy efficiency of its drives.

Living up to responsibilities

“We believe that sustainability goes even further than that, though,” he says. “We are determined to live up to our responsibilities in every way, whether in relation to the environment, our customers, our business partners, our employees, and not least our children and the world in which they will live.”

Through a long-term sustainability initiative called sustainability@SEW, the company is gradually and consistently safeguarding resources, lowering CO₂ emissions and optimising its entire value chain. Much progress has already been made, as it has for many years adopted a philosophy and practical approach that is centred on sustainable, durable products and an unwavering focus on customers and their requirements.

This ‘cradle-to-cradle’ approach – established back in 1990 as an end-to-end system for a circular economy – is now a benchmark for the environmentally friendly development of products and associated processes. It means that all the products, materials and substances used to manufacture a product can be fully returned to, or reused in, biological or technical loops.

Eco-design

This holistic approach is really the basis for planning the roll-out of SEW-EURODRIVE’s in-house eco-design guidelines. An example of how this is applied can be found in the way the company is developing and documenting two projects already underway on the recycling of brake components and magnets. These projects will provide a basis for eco-design to extend to the product categories of motors and electronics.

Another project will take these findings further and incorporate more product families. With its depth of expertise built from its sustained commitment to quality, SEW-EURODRIVE is opening a completely new chapter in product design with this sustainable product concept development. Its design guidelines will be distilled it into practical recommendations such as avoiding the use of certain adhesives or casting resin.

Reuse and recycling

The company will also produce an extended product qualification system as a benchmark for product development. Among the focus areas are reuse and recycling, which give many components a second lease on life. The scope of recycling is to be maximised, while leveraging a reuse system that puts as many products as possible back into service.

This means inspecting and cleaning reusable parts to possibly be fed back directly into the production process. This saves on the energy required to recycle copper, steel and die-cast aluminium parts – including the transport, separation and melting down of used parts.

Gear lubricant from sustainable biomass

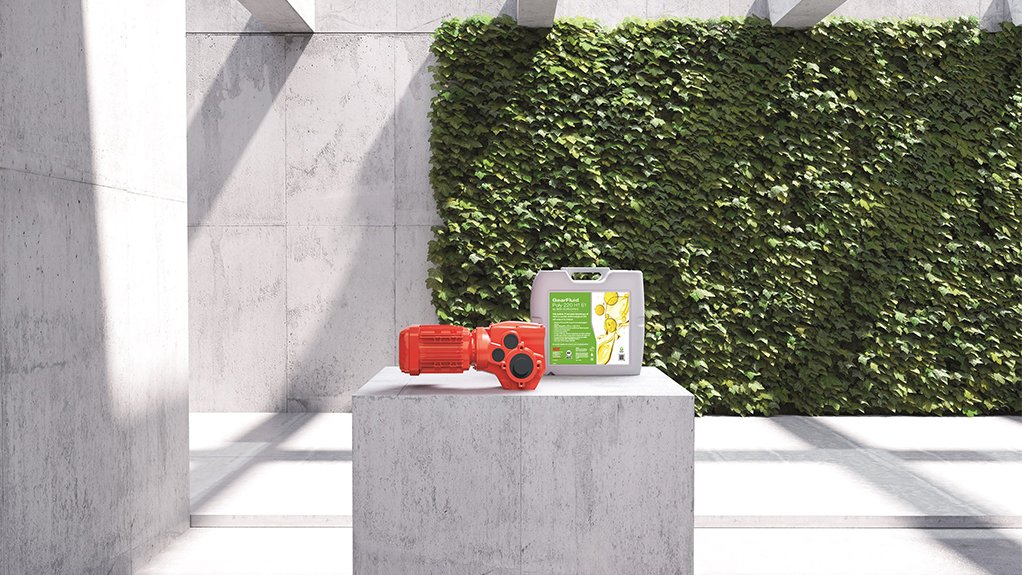

In another sustainability innovation, SEW-EURODRIVE has developed a CO2-reduced lubricant for its gear units. With 90 years of experience in developing and building gear units, the company has considerable expertise in tribology – the study of friction, lubrication and wear. Last year, it launched GearFluid Poly 220 E1, the first CO₂-reduced gear unit lubricant made from sustainable biomass – rather than from petroleum or another fossil raw material.

This improves the carbon footprint of GearFluid by 84% compared to petroleum-based polyglycol base oils. The biomass we have developed does not even need to be specially produced, and it takes up no additional agricultural land. Instead, the biomass comes from green cuttings and food waste, which is readily available and can now be very easily recycled.

This biowaste undergoes a complex synthesis process that transforms it into a high-quality base oil. The packaging has also been designed with sustainability in mind, so there is 25% recycled plastic in the cannisters for the oil.

Sustainable service

SEW-EURODRIVE’s holistic sustainability focus extends to the service end of its business – demanding that its products should always be designed to be as maintenance-friendly and repair-friendly as possible. An example of this is how gear units and gearmotors can be disassembled non-destructively and then reassembled again once faulty or worn parts have been replaced. Extending the service life of existing products also means having all individual components available worldwide for decades – to avoid unnecessarily using up resources on new equipment.

The company’s Life Cycle Services are the next logical step in this approach. These services are based on the concept of a holistic, closed loop that covers a product’s entire service lifespan while in use with the customer.

Provided by a dedicated contact, customers receive the best possible expertise and advice for their drive technology. An illustration of how this supports sustainability is the maintenance-friendly connection between SEW-EURODRIVE’s gear units and motors. This connection is made with a pinion shaft that has a key and a mounted pinion with a corresponding slot. Unlike on crimped pinions, this connection can be disassembled without destroying the parts. Any necessary repairs can be carried out at the customer's premises or in one of SEW-EURODRIVE’s service centres.

In conclusion, Blickle emphasises how SEW-EURODRIVE works hand-in-hand with dedicated people to ensure the company is focused on people and on the future of humankind.

“Maintaining and protecting the very basis of our existence – that is exactly what sustainability means and that is what drives us at SEW‑EURODRIVE,” he says.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation