Frankwen Forge

Founded in 1981, Frankwen Forge has grown into a key manufacturing and engineering business. Its quality products and services are used in a number of industries, including the mining, petrochemicals, power generation, marine and general engineering sectors.

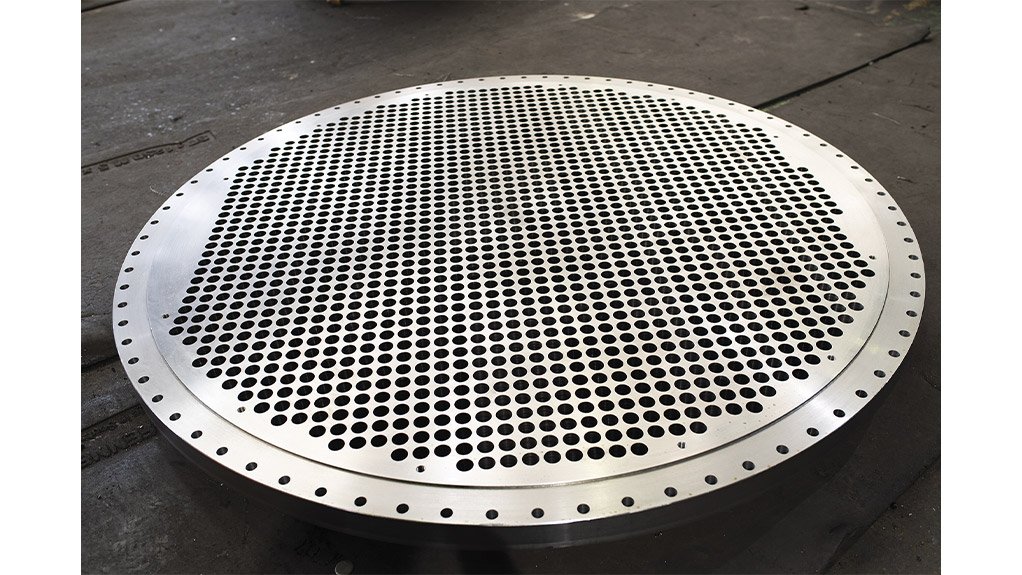

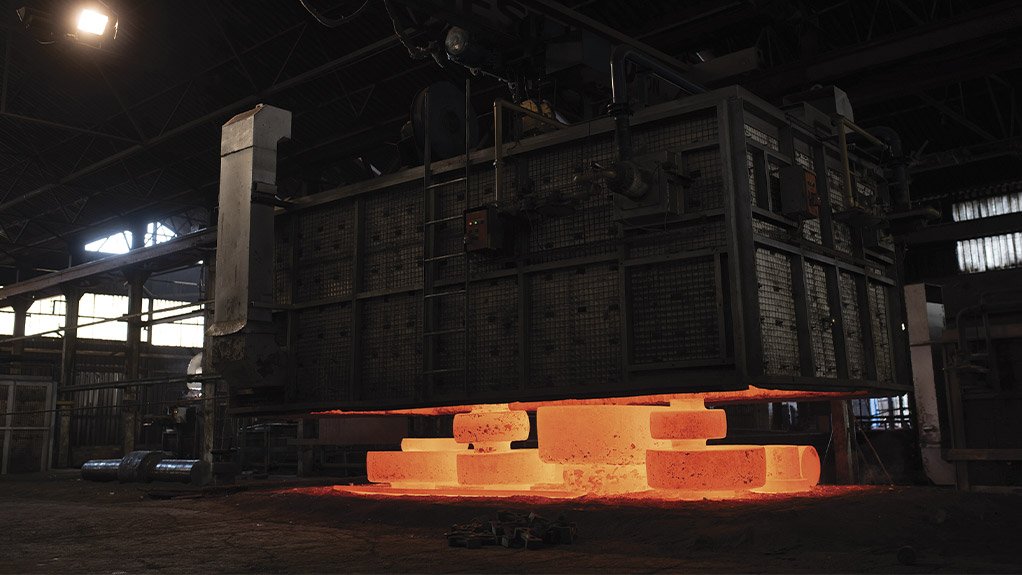

Frankwen Forge has a unique and diversified manufacturing facility that offers a large variety of forgings including seamlessly rolled rings, various heat treatment services, deep surface salt bath hardening, rough or final machining as well as operating a special steels division. Frankwen also has a SANAS accredited laboratory on site called Franktech (www.franktechlab.com).

The company’s forging capabilities include:

- Bars or shafts from 100 mm to 850 mm in diameter and up to 7 500 mm in length, either stepped or parallel

- Gear blanks up to 2 000 mm in diameter and 650 mm high

- Various rings up to 2 800 mm in diameter and 650 mm high

- Bushes up to 1 500 mm in diameter and 1 200 mm high

- Forgings from 10 kg to 10 tons

Frankwen Forge heat treatments include the following:

- Normalising up to 8 m long

- Stress relieving sizes up to 8 m x 3 m x 1.5 m

- Annealing up to 8 m long

- Solution heat treatment of aluminium forgings

- Oil and water quench bars up to 7.3 m long and 3 m high

Frankwen Forge keeps up with the latest international standards and testing methods used across various sectors. In addition, the company supports customers by providing technical expertise, including engineering drawings, as part of its overall drive towards customer satisfaction.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation