Enable safer machine interventions with Lockout/Tagout

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

A large number of workplace accidents is connected with industrial machine maintenance. Because of this, a serious safety programme should include processes to increase the safety of interventions on machines. A tested way to reduce workplace accidents during maintenance, is the use of Lockout/Tagout.

What is Lockout/Tagout?

The Lockout/Tagout procedure prevents injuries connected with maintenance such as fractures, lacerations, amputations, burns and shocks. It is a planned safety procedure which involves the isolation and inoperability of the energy supply of industrial machinery during maintenance.

“Lockout/Tagout procedures vary in different companies, but they usually have the same building blocks”, says Oliver Fernau, Product Manager Safety & Facility Identification at Brady Corporation. “These include a written policy including prescribed Lockout/Tagout operating sequences and a definition of roles and responsibilities; padlocks and unique keys adapted to the working environment; and dedicated devices to block energy sources in the “off”-position.”

Written policy and procedures

Central in any Lockout/Tagout programme is the written, company wide policy. “In many companies this is a 20 page document. But it can grow quite easily to 200 pages in large multinationals. The Lockout/Tagout procedure is usually signed by the Health & Safety Manager, Production Manager and top executives within the company.”

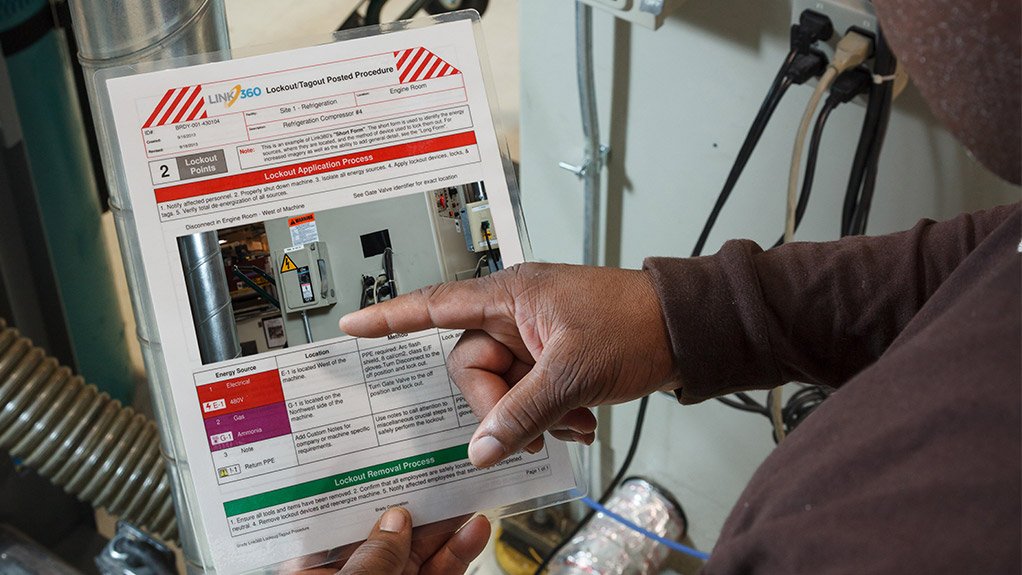

Added to the policy should be detailed, step-by-step descriptions of how to lock out various energy sources per machine present in the company. Brady suggests to visualise every energy control point that needs to be locked out, and to offer distinct steps in a clear layout for optimal procedure communication.

Equally important as isolating machinery from its energy supply before maintenance starts, is informing employees on how to safely reactivate machinery when maintenance is done. “Steps could include making sure the work is completed, cleaning up all tools and work-aids, checking guards and controls and notifying employees the locks are being removed.”

3 roles to identify

Every employee plays one out of three roles in any Lockout/Tagout programme:

Authorised employees are the only ones who can lock out equipment. These employees need rigorous training in the Lockout/Tagout procedure. They need to know where the energy sources are for every machine they service, how to isolate them safely, and how to do their job without risk.

Affected employees, whose work can potentially be affected by Lockout/Tagout. They need to be very aware of the importance of the procedure and they need to know what to do if their machinery is locked out.

Next to affected employees, there will always be employees whose work could never be affected by Lockout/Tagout. It is, however, important to inform them about the significance of the procedure to make sure they refrain from tampering with any locks.

Training and/or communication for these employee categories, is of major importance for the quality of the Lockout/Tagout procedure in any company.

The right lock is the key to safety

When the Lockout/Tagout procedure is written, it is time to source the tools to support the programme. Choosing the right padlock for your working environment is an important step. These locks are in place to prevent employees from inadvertently re-energising machinery and putting your maintenance workers at risk.

The working environment determines which padlock to use. In electrical applications non-conductive padlocks are the best choice. For electrical panels, lightweight padlocks are preferred. Aluminium padlocks have superior durability in humid or in outside environments.

Colour-coded padlocks help recognising who locked out an energy source when multiple maintenance teams are active.

Every padlock can have a unique key, making it impossible to open a second lock with the same key. Unique keys guard an important lockout/tagout principle: only the individual who placed the lock, can remove it. The use of a master key or grandmaster key should always be a last resort and must be described in the Lockout/Tagout procedure.

Dedicated lockout devices

Dedicated lockout devices exist for every type of energy control point, including handles, push buttons, valves or other mechanisms that allow energy to flow to a machine. “When applied correctly, a Lockout/Tagout device will block an energy source in the ‘off’-position, making it impossible to re-energise machinery without removing the padlock, or padlocks, on the lockout device. To decide which devices you would need for a succesful Lockout/Tagout programme, you need to map all energy control points present in your company. It is very important not to miss any energy control points, because if they are not locked out, servicing a machine will never be safe.”

Time for action!

“If you are faced with a number of maintenance accidents, or increasing risks and near misses during maintenance, I believe it is time to seriously consider Lockout/Tagout. The procedure will help you reduce workplace accidents, reduce lost working hours due to recovery from injury, and reduce litigation risks for your company.”

“A great way to start a Lockout/Tagout programme, is inviting a specialist to perform a Lockout/Tagout audit in order to map all energy control points present in your company. When these are identified, selecting the right lockout devices and locks becomes easy. A list of tools will, in turn, help to write clear and dedicated step-by-step lockout procedures.”

Brady offers expertise, services and all the tools to reduce workplace accidents during machine interventions with Lockout/Tagout. For more information, get the free Lockout/Tagout guide via www.bradyeurope.com/lockouttagout.

Lockout/Tagout regulation

The Lockout/Tagout procedure has proven to be so successful that the procedure became obligatory for all industrial maintenance in the United States where it is enforced by OSHA, the US Occupational Safety and Health Administration.

In Europe, the Directive 2009/104/EC – use of work equipment specifies minimum requirements for safety and health while using equipment. European Directive CEE 89/455 outlines minimum regulations for the safety and protection of employees when servicing industrial equipment and the EN 1037 norm defines measures regarding energy isolation of machinery to prevent hazardous equipment re-energising. While Lockout/Tagout is not mentioned literally in any regulation in Europe, except in France for electrical applications, it is widely considered a best practice to guarantee optimal safety during maintenance.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation