Emirates Global Aluminium orders seventh Hertwich batch homogenizing unit

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Emirates Global Aluminium has placed an order for the supply of an additional batch homogenizing furnace for the heat treatment of billets with Hertwich Engineering, a company of the SMS group. Including this new unit, which will go into operation at the end of 2017, a total of five batch furnaces of this type will be operating at EGA’s Jebel Ali plant and two at EGA’s Al Taweelah smelter.

Emirates Global Aluminium is one of the largest industrial companies in the United Arab Emirates outside oil and gas. Its production makes the UAE the world’s fourth largest aluminum producing nation. EGA has smelters in both Jebel Ali in Dubai and Al Taweelah in Abu Dhabi.

The cooperation between EGA in Jebel Ali and Hertwich goes back to 1994, when the first continuous homogenizing plant was commissioned at EGA. In 2010, EGA was also the first company to place its trust in the newly developed Hertwich batch-furnace concept. Due to the positive experience gained, EGA is subsequently replacing all its older batch furnaces in Jebel Ali with modern units from Hertwich. The fourth unit started operation in the autumn of 2015; the batch furnace currently on order will be the fifth of its type at this aluminum plant. Including the two batch furnaces in operation at the Al Taweelah plant, EGA will soon operate a total of seven Hertwich batch homogenizing units.

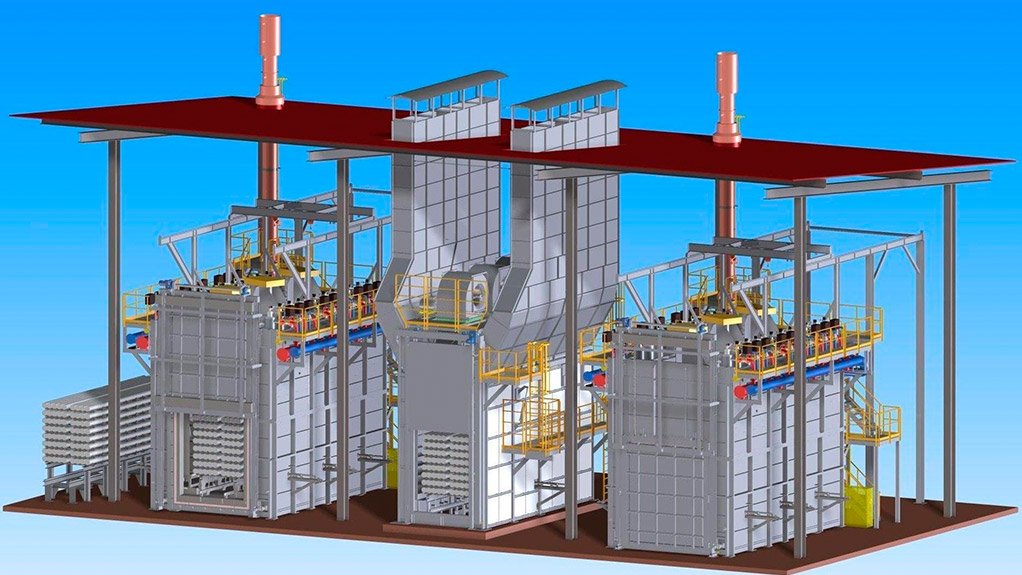

The new furnace is designed for use with billets 125-406 millimeters in diameter and 5,000-8,000 millimeters long. During heating in a conventional batch furnace, the gas stream loses energy as it passes through the stack of material being heated; the new design achieves more uniform heating of the furnace contents by alternating the direction of the incident gas flow. Experience has shown that heating-up times can be reduced significantly in this way. A new feature of the fifth homogenizing unit is that certain alloys can also be cooled down in the furnace. The temperature range is 620-450 °C.

Where cooling is carried out in a separate cooling station, air from the casthouse is sucked in via fans and passed through the stack of material being cooled, the direction of the incident gas flow is alternated here too.

The ancillary equipment required for furnace operation has already been supplied with the existing furnaces and can be used for the new furnace. It facilitates a large degree of automation of the heat treatment process. This begins with the loading of the trolley and incorporates a whole host of subsequent steps: stacking with automated spacer handling, ultrasonic testing, furnace charging and operation, transfer to the cooling station and unloading the stack, sawing, weighing and packaging.

Batch homogenizing plant and cooling station, schematic view

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation