Emerson Launches New Drilling Jar Clamp For Increased Safety And Well Integrity

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Clamp can be used for drilling, DST jars, coil tubing and wireline applications

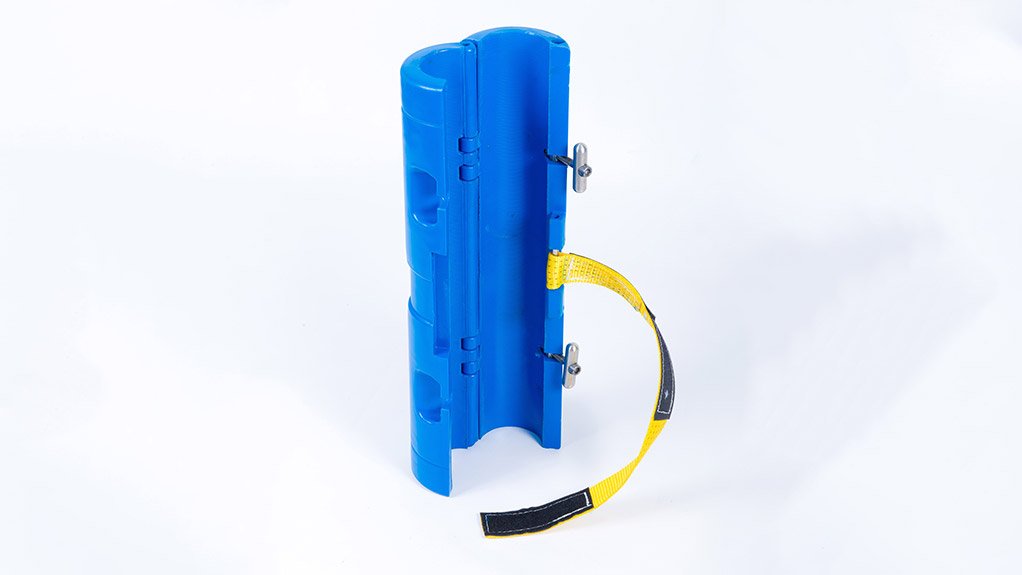

Emerson Automation Solutions has launched the latest product within its polymer completions solutions range – the PolyOil® JAR Handling Clamp – for increased safety and well integrity.

One key threat to well integrity and safety in drilling and completions operations today is the danger of jars firing prematurely at the surface prior to being deployed into the well. Jars are mechanical devices used downhole to deliver an impact load to another downhole component (especially when that component is stuck) and include a firing mechanism that activates when the necessary compression or tension has been applied to the running string.

The inadvertent firing of such jams prematurely, however, can pose a hazard and lead to possible injuries and the dropping of the bottom hole assembly if pins are sheared.

The new PolyOil JAR Handling Clamp acts a safety device to prevent the jar from cocking and firing, with the jar unable to fire unless the fishing neck – designed to enable running and retrieval tools to reliably engage and release – is closed.

Therefore, when the clamp is fitted to the jar, the rod is kept in the open position, thereby preventing premature firing during the handling of the jar at the surface. The clamp also prevents the jar rod from being damaged during transportation and keeps it debris-free during storage. Applications for the new JAR Handling Clamp include drilling, drill stem testing (DST) jars, coil tubing and wireline applications.

Said Matthew Armstrong, director downhole operations for Emerson’s PolyOil/Roxar business: ”Our PolyOil solutions are all about bringing predictability, safety and innovation to downhole drilling and completions. This is what we have achieved with the PolyOil JAR Handling Clamp, improving the effective operation of jars, the well’s integrity and – most importantly of all – personnel safety.”

The PolyOil JAR Handling Clamp and many other PolyOil products use a range of high impact wear resistant materials with the natural properties of the polymers making them low weight, safe, easier to handle than metal, and more resilient.

Other key features of the clamp include a hinged design with the clamp simple and fast-to-fit and a toggle/swing bolt for fast latching operations.

The PolyOil portfolio of subsea and downhole completion products is based on bringing modern materials technology to drilling and completions. Many standard designs as well as customized designs are available within very short lead times. PolyOil solutions have been deployed worldwide, including the North Sea, the Gulf of Mexico and offshore Brazil.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs.

Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation