Electra Mining Africa: the best of cutting edge technology

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

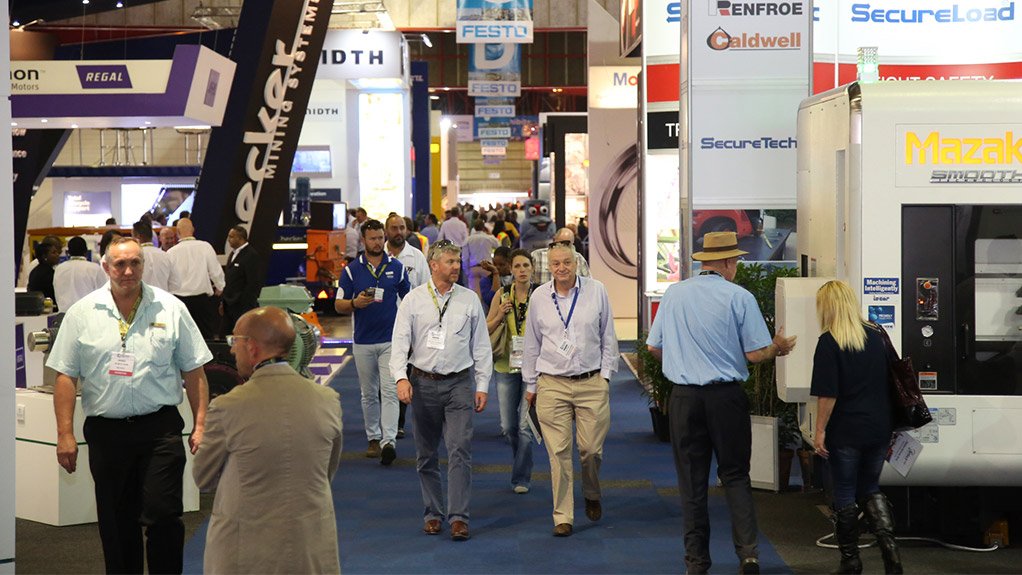

Technology, a key driver in engineering and mining innovation, is being driven by the commodity downturn. This year’s Electra Mining Africa saw a host of these innovative technologies being showcased, demonstrating the local engineering and mining industry’s world class status in terms of producing products and services that provide a safer mining environment, that is more efficient in terms of production but also more adaptive.

It is important that the industry move to technology solutions because the environment it operates in is changing says Raymond Padayachee, Head of Process Industries and Drives, Siemens. “Traditional technologies can no longer keep up with the demands of our changing world. This is the age of digitalisation and mass custom production. Siemens is at the forefront of the driving the age of digitalisation via Industry 4.0.”

A demonstration of this is the FESTO Air Penguin. Part of the company’s Industry 4.0 philosophy, it is used to demonstrate what technology can do in a way that everyone can understand. The project was inspired by nature and how animals and insects move and interact.

Developed by its bionics department, Russell Schwulst, Head of Business Development for FESTO, explains that the Air Penguin, in considering factors such as air conditioning, side drafts, etc. is constantly adapting to its environment. “It decides this itself. In the manufacturing process this would mean seamless production as machines would talk to each other to either ramp up or down production.”

In a complete break with tradition, this year saw Sandvik’s stand empty of equipment. Simon Andrews, Vice President, Sandvik Mining Sales for Southern Africa explains that this break with convention is a demonstration of the company’s new approach. “Previously we sold products. Today we are selling solutions, because this is what the industry is asking for.”

The stand hosted a Virtual Reality experience as well as a mining tunnel. “This way of exhibiting enables us to demonstrate our solutions, from cradle to grave, and a different way of working that is of more benefit and adding more value to the industry.”

3D Printing is a great solution when a company has a strong technical and business case as it can produce at a lower cost in a shorter time. Mass customisation and complexity are two things that 3D printing does well explains David Sean Bullock, the owner of Rapid 3D. “In the mining industry 3D printing is being used to create models and designs for display and training purposes.” He adds that in the future, 3D printing will mean that engineers and designers will not be held back by conventional techniques.”

A major highlight was the locally produced Continuous Miner (CM) from JA Engineering (JAE). The development of the CM is all about contributing to the industry and keeping the mining industry in South Africa sustainable, says JAE Chief executive Danie van Wyk. “It has also brought about more employment opportunities in the country. JAE alone has already doubled its production capacity and added additional factory space. We want sustainable long term employment through sustainable growth.”

The Department of Trade and Industry (dti) worked closely with the company on the project. Tapiwa Samanga, Chief Director, Primary Minerals, at the dti, called the CM a “demonstration of collaboration between South African suppliers and mining houses with the government as a facilitator.”

Kal Tire provides tyres and the maintenance of tyres to the mining industry. It has developed a unique new repair process for tyres that would otherwise have to be destroyed. “Our theme is innovation, so our stand hosts a number of new products and developments, all of which provide our customers with a more efficient, safer and lesser work load,” explains Peter Larsen, Vice-President for Sales and Safety at Kal Tire.

Customers are concerned about safety, managing the human element and recycling. “We have developed a recycling process that breaks down the tyre into three components - carbon black, oil and steel. Each of these can be used on their own in other products.”

The process can recycle 20 tons of tyre per day, yielding 28 000 carbon black, 750 kg of steel and 2 500 litres of oil.

Showing just how innovative the engineering sector is in South Africa is a new product from the Northern Cape. Designed, developed and manufactured by Rapid Armour, the start up company is less than two years old. Its product is an idea that is completely out of the box, explains, Morne van der Merwe, owner of Rapid Armor. “We looked at the lifecycle of conventional linear systems in the industry, and developed the dynamic liner system.”

The system is revolutionary and changes the way maintenance is done on linear systems in mining and quarrying plants. The systems can be maintained up to 10 times faster than the conventional liner systems, yet it is safer.

He says Electra Mining has proved to be the perfect launch pad for the product. “Electra Mining allows me to see multiple customers and businesses every day; something I would not be able to accomplish on my own. It is also a good place to see what developments are taking place in the industry.”

This year the show saw over 850 exhibitors showcasing cutting edge products and technologies with live demos and interactive product displays as well as content rich conferences and free to attend seminars.

Show organisers Specialised Exhibitions Montgomery is a member of the prestigious Montgomery Group, one of the most widely respected exhibition companies in the world with trade shows, consumer shows and specialist projects currently spanning Europe, the Middle East, Africa and Asia.

For information on Electra Mining Africa 2018, go to www.electramining.co.za or for further information contact Leigh Miller at email leighm@specialised.com

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation