Effective component protection with Plasma Transferred Arc welding process from Thermaspray

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The Plasma Transferred Arc welding and hardfacing process from surface engineering and coating specialist, Thermaspray (Pty) Ltd., is a versatile, high temperature, wear- and impact-resistant welding process that guarantees a high quality weld deposit making it ideal for protection of components in severe impact, wear and corrosive environments.

First introduced to the welding industry in 1964 as a method to bring better control the arc welding processes in lower current ranges, the PTA process provides a versatile method of depositing high quality metallurgically fused deposits on relatively low cost substrates to protect components against sever corrosion or abrasion, thermal shock, slurry erosion or impact forces.

The plasma welding torch contains a non-consumable tungsten electrode (-) located within a copper nozzle (+) with a small opening at the tip. A pilot arc is struck between the torch electrode and the nozzle tip and the arc is transferred to the metal to be welded. By forcing the plasma gas and the arc through the constricted orifice, the torch delivers a high concentration of heat to a small area which leads to high quality welds. The deposit alloy powder is conveyed from a hopper to the torch by a carrier gas.

Complimentary to both thermal spray and conventional welding, PTA can be applied in practically every case where hardfacing is needed, making it ideally suited to a wide range of applications.

An extensive variety of materials, ranging from soft / medium hardness (e.g. stainless steel) to very hard, wear resistant materials (e.g. carbide composites), can be deposited using the PTA process to achieve diverse surface properties such as mechanical strength, wear, corrosion and creep resistance, delivering excellent reproducibility from batch to batch. Bead thicknesses range from 1.2 to 2.5mm and multi-pass runs depend on the application.

According to Hoosain, the plasma transferred arc process offers a number of important advantages over conventional arc welding processes. “Precise metering of metallic powder feedstock means that less material is used compared other traditional welding processes. The precise control of important weld parameters ensures a high degree of consistency from batch to batch while controlled heat input (which less than other conventional arc welding processes), ensures weld dilution control of between 5-7%.

Additional benefits delivered by the PTA process:

- Produces a deposit of a specific alloy that is tougher and more corrosion resistant than counterparts produced through GTAW and OFW.

- PTA weld deposits have characteristically less oxides, inclusions and discontinuities.

- Post weld machining is minimised due to the smooth deposit created through the PTA process.

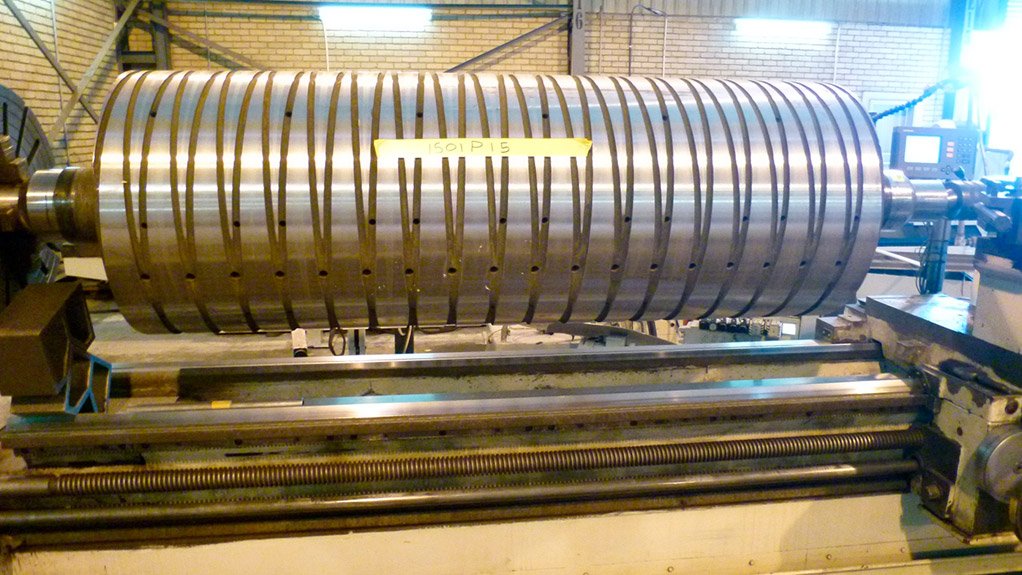

Typical applications of the PTA process offered by Thermaspray include Pot roll (Journals with cobalt-base process roll, high temperature wear and corrosion resistance); scraper blades (wear area of scraper blade PTA welded with cobalt-base alloy for high temperature wear resistance); Scraper rings (gearbox components with cobalt-base alloys. Wear and abrasion resistance and high temperature steam valve components (valve seats with cobalt base alloy). “Components used in glass manufacturing are PTA welded with a Ni-based alloy to provide impact and wear resistance at high temperatures,” adds Hoosain.

Alongside PTA welding, Thermaspray also provides a comprehensive range of support coating finishing technologies including machining, grinding and burnishing from its state-of-the art facilities in Olifantsfontein, Johannesburg.

Thermaspray, in a joint venture with Cape Town-based Surcotec, offers an extensive portfolio of engineering and thermal spray coating solutions that extend component life cycles to assist OEM and end-user clients across southern Africa in reducing costs and increasing production. The companies’ world-class quality wear- and corrosion-resistant thermal spray coatings, Plasma Transferred Arc (PTA) cladding and Polymer coatings (in partnership with Plasma Coatings USA and Diamant Metalplastic Germany) are augmented by a host of specialised allied services.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation