Ecofriendly brake pad sets benchmark

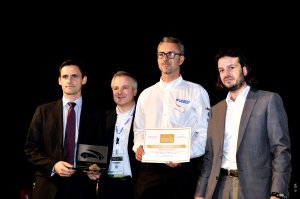

TAKING HOME THE GOLD Eco-Friction brake pads secured a gold trophy in the aftermarket and retrofitting category at the Equip Auto 2013 International Grand Prix for Automotive Innovation Awards

Automotive supplier Federal-Mogul, the holding company for Ferodo brake products, launched the first copper-free Eco-Friction brake pads in October last year. The friction formulation is designed specifically for the Toyota Quantum taxis.

Federal-Mogul technical adviser Bertie Steyn explains that the company has developed an ecofriendly friction formulation, which improves brake pad performance and reduces wear in the brake rotors and of the brake pads.

“In the future, all brake pads will go green. We want to be the first company to have an entirely green range,” he says.

In 2010, the company conducted 70 field fitment tests on 70 sets of brake pads and brake rotors fitted to vehicles in taxi ranks across South Africa. Extensive dyno-testing was also conducted to replicate driving conditions in a controlled environment. The last field test with the new and improved friction formulation was conducted in August 2013, adds Steyn.

“The testing was conducted [as] the conditions in South Africa are different to those in Europe and this formulation was specifically designed for the South African environment,” notes Steyn.

After testing, the company also engaged with taxi drivers, who all gave positive feedback on the performance and life span of the new product tested.

Meanwhile, the Eco-Friction brake pads secured a gold trophy in the aftermarket and retrofitting category at the Equip Auto 2013 International Grand Prix for Automotive Innovation Awards, held in Paris last year.

Federal-Mogul vehicle components segment VP and GM Martin Hendricks explains that more than one-million new vehicles from leading original-equipment light vehicle manufacturers will be equipped with Federal-Mogul’s Eco-Friction pads during 2014.

Steyn says the brake pads were manufactured locally at the company’s plant in Prospecton, Durban, noting that development took place both in South Africa and at overseas testing facilities.

He explains that heat dissipation is one of the biggest challenges for mechanics during brake applications. Owing to this, the company developed this formulation to maintain increased stopping distances and insured speedy recovery rates after extreme braking applications, even when elevated operating temperatures during operation are reached.

“Dyno and fuel testing was carried out, as the South African environment differs from those abroad,” notes Steyn, adding that testing was necessary because the brake pads were designed specifically for the South African taxi industry.

After testing, the company also engaged with taxi drivers, who all gave positive feedback about the new brake pads, he says.

He adds that the life span of the brake pads depends on the vehicle and other factors; however, it is evident that some brake pads of competitors crumble, as they cannot handle continuous heating and cooling.

Other challenges, says Steyn, include providing the correct information about the ecofriendly pads for end-users, and setting a competitive price in light of the new formulation.

The future success of the brake pads, therefore, depends on the perception of the market, and Steyn notes that these perceptions changed significantly when the difference in quality was demonstrated.

All brake pads have to conform to the European quality standard ECE regulation 90, which prescribes that linings should be tested for speed sensitivity and cold performance, with replacement brake pads and brake shoes permitted to deviate from the frictional characteristics of their original-equipment counterparts by not more than 15%.

Steyn adds that the Eco-Friction brake pads exceed these minimum requirements, but emphasises that the brake pads should be used only for the Toyota Quantum taxi, as its design is application specific and load transfers can be different.

Federal-Mogul brand manager Alfred Adriaan concludes: “The taxi business forms a large part of the South African economy; therefore, safety should be a huge priority, as a lot of people rely on public transport.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation