Innovations help supplier service advancing industry

IOT SUPPORTED PUMP CONTROL The Ds500 offers IoT enabled remote assistance monitoring and touch-screen control

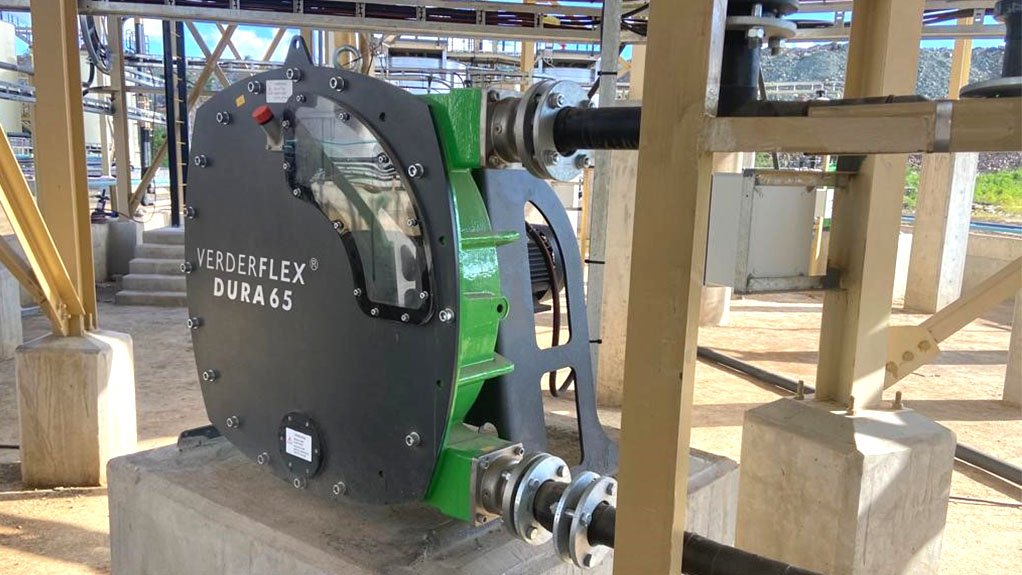

INNOVATIVE PUMP TECHNOLOGY The Verderflex Dura 65 peristaltic hose pump won the Global Business Excellence Award for Outstanding New Product or Service in 2022

Integrating Internet of Things (IoT) capabilities into its pump technologies is one way through which industrial equipment supplier Verder Pumps South Africa is keeping up with digital transformation, states Verder Pumps South Africa MD Darryl Macdougall.

Digital transformation remains one of the most significant drivers of technological advancement across different sectors, particularly for mining and mining technology.

An example of this technological integration is Verder’s Verderflex Ds500 metering and dosing pump, which was launched locally in July 2022.

Designed to address inherent challenges in other traditional technological solutions, the Ds500 can result in a greater dosing accuracy of about 1%, reducing chemical consumption and costs, he adds.

In addition to providing the benefits of peristaltic pump technology, the Ds500 also offers IoT-enabled remote assistance monitoring and touch-screen control.

“It is easy to set up and use, reducing indirect costs through minimal, tool-free maintenance and servicing requirements. The remote assistance supports monitoring, but does not control the pump. This not only ensures accuracy in processes but also allows one to record performance, plan maintenance and receive alerts on problems that prevent downtime.”

The Ds500 comes standard with a high-definition, full-colour, 4.3-inch thin-film touchscreen.

Verder Pumps South Africa is a significant role player in niche market and industrial pumping solutions, says Macdougall.

“Our diverse pump and technology portfolio includes our well-known brands like Packo, Verderflex, Verderair and Verdermag. As the company’s leadership has continued to back our research and development teams, we have launched several new pumping solutions and award-winning ‘facelifts’ on already popular ranges over the last two years.”

For example, the Verderflex Dura 65 peristaltic hose pump won the Global Business Excellence Award for Outstanding New Product or Service in 2022.

The pump boasts 20% better flow rates and can pump 20% more volume through the hose with every revolution.

Based on feedback from users in the field, Verder has also developed the Verderflex Dura 80 Hose pump – a next-generation peristaltic hose pump with increased functionality that boasts high-performance swept volume. It is designed for applications such as metering and transfer duties, with a focus on sludges, slurries and abrasives.

Macdougall states that emerging technology, such as peristaltic or hose pumps, can contribute to enhancing returns in processing operations where the crushed ore is turned into slurry by adding water.

Further, Verder’s innovative peristaltic pump technology offers several advantages for mining applications.

Firstly, the pumps using this technology are cost effective and require less initial investment, as well as less overall maintenance costs and fewer instances of downtime, which, in turn, provides mines with a higher return on capital, and simplified operations.

Secondly, the company’s peristaltic pump technology also promotes water efficiency, as the pumps can save water through dilution, and they require less space and power than conventional pumps.

The technology also poses less risk of chemical leakages by eliminating leaking seals, which results in less chemical waste or damage and, thereby, less pollution and waste affecting the natural environment.

Case Study

Verder highlights the hidden costs of buying a “low-priced, but surprisingly expensive” peristaltic hose in a recent case study, conducted at one of the largest copper producers in the Southern African Development Community region.

For commercial reasons, the mine chose to fit a hose not manufactured by an original- equipment manufacturer (OEM) in a Verderflex DURA hose pump.

“Production bore the brunt of this commercial decision, as the ‘low-priced, but surprisingly expensive’, hose’s failure rate was an average of three failures a week, resulting in production stoppages.

Owing to production stoppages, Verder was asked to investigate the reason for the failures and present a solution. The remedy was simple – fit an OEM hose.

Macdougall says the OEM hose was fitted to the DURA pump and was run under the same operating conditions.

The Verder OEM hose that was installed in December 2021 ran continuously for eight months without any failures that could result in loss of production.

The achieved cost saving has far outweighed the cost saving of the “low-priced, but surprisingly expensive” hose, Macdougall concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation