Deep learning solution to transform ore sorting technology

TOMRA's software, known as OBTAIN, is a cutting-edge solution that leverages deep learning

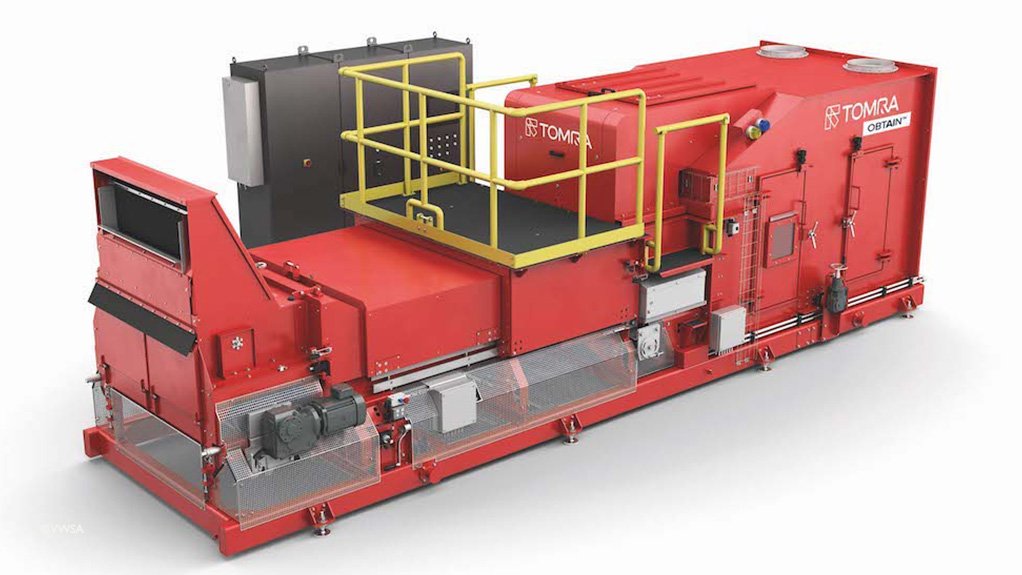

Sensor-based ore sorting technology provider TOMRA has unveiled its latest innovation for high-capacity ore sorting at the Investing in African Mining Indaba exhibition in Cape Town, South Africa.

This ground-breaking software, known as OBTAIN is a cutting-edge solution that leverages deep learning to bring single-particle precision to high-throughput particle sorting, taking capacity, quality and recovery to a new level and unlocking value through a wealth of extremely detailed and accurate data for better-informed decision-making.

TOMRA Mining head Albert du Preez shared his insights into how OBTAIN marks a significant leap forward in sensor-based ore sorting technology in an exclusive interview with Mining Weekly.

“The primary achievement of OBTAIN lies in its capacity independence,” explains du Preez.

The technology enables a potential doubling of capacity in each application, simultaneously improving recoveries and lowering yields, thanks to its precise algorithm. This breakthrough is poised to redefine the efficiency and capabilities of ore sorting machinery.

TOMRA has a rich history dating back to 1993, and du Preez highlights the company's extensive use of Artificial Intelligence (AI) in its sorters.

“While AI has been integral to TOMRA's sorting technology for many years, OBTAIN represents the incorporation of deep learning for the first time, signaling a new era of advancements in the field.”

Du Preez emphasises the tangible improvements achieved through OBTAIN over the last decade. Extensive testing with clients over one and a half years showcased the capability to double capacity, increase recovery and reduce yield while maintaining the same efficiency. This opens doors for mining operations to explore new opportunities and extend the lifespan of their operations.

OBTAIN's strategic unveiling at the Mining Indaba aligns seamlessly with TOMRA's recent product launch, the TS100C ejection module (valve). “The combination of OBTAIN's deep learning and these valves allows for efficient sorting in much smaller size ranges, unlocking untapped value in areas such as copper, gold and other ores down to 4 mm,” he notes.

One of the notable features of OBTAIN is its applicability to existing sorting machines. Du Preez clarifies that OBTAIN integrates with TOMRA's latest generation of sensors, with new machines ready for immediate use and older ones requiring a minor hardware update for retrofitting.

He expressed his excitement about the potential impact of OBTAIN on the sorting industry. With a focus on stability and efficiency, OBTAIN addresses previous challenges faced by operators in feeding machines correctly. The technology ensures stable efficiency regardless of variations in operator behaviour, which is particularly crucial for sorting fines.

When asked about potential competition, du Preez acknowledged that others may follow suit but stressed the complexity and time required to develop and test deep learning solutions. Despite potential competition, he sees the industry benefiting from advancements in sorting technology.

Market reactions are yet to be disclosed, but du Preez confirmed that clients involved in testing have shown tremendous interest and satisfaction. With the promise of doubled capacity and enhanced efficiency, OBTAIN has set the stage for a transformative era in sensor-based ore sorting technology.

“This is an exciting innovation that marks the beginning of a new era in sensor-based sorting and will enable mining operations to unlock untapped value and extend the life of their mine,” concludes du Preez.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation