CSIR Aeronautics attracting international clients as SA budgets fall

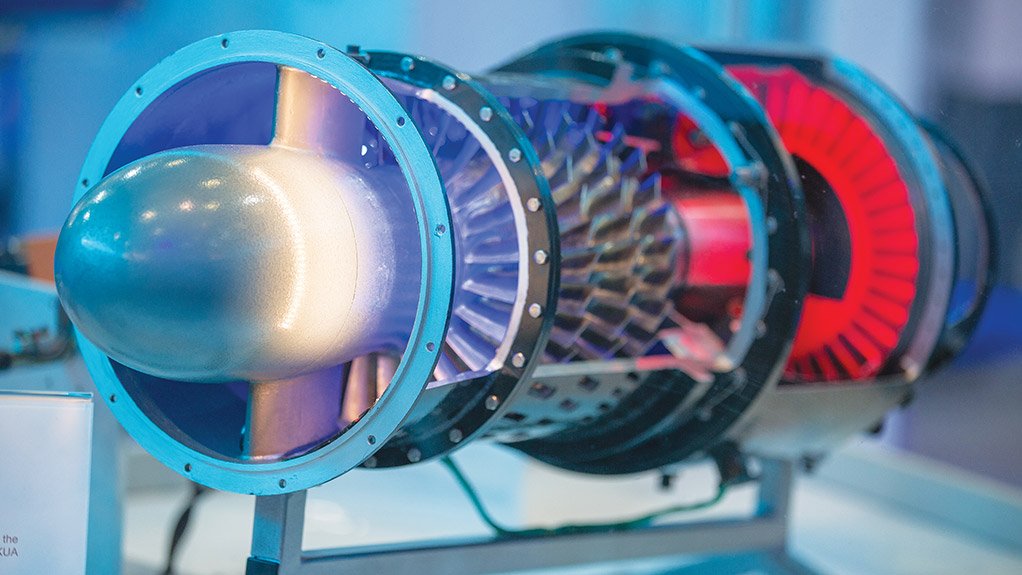

MAJOR PROJECT: A CSIR mock-up of a small gas turbine engine

Photo by CSIR

LIGHTER THAN AIR Readying the aerostat for an early-morning test flight

Photo by CSIR

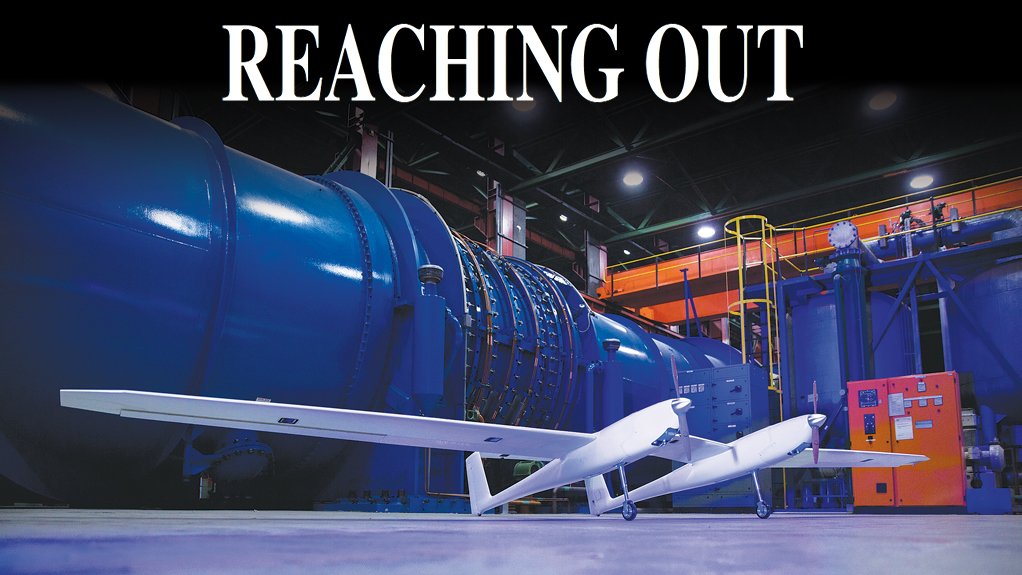

MATURE WORLD-CLASS CAPABILITY A half-model of an airliner inside one of the CSIR’s wind tunnels

The Council for Scientific and Industrial Research (CSIR) Aeronautics Systems Competence has created an innovation team – a description, not a title – to address both emerging opportunities and problems in the global aerospace environment.

It amounts to the creation of a new portfolio within the competence area, which combines aeronautics, aerodynamics, computer modelling and simulation, design, systems engineer- ing, systems development and integration. CSIR Aeronautics Systems has three key business areas: aeronautics test and evaluation; aeronautics systems development, integration and innovation; and providing sound aeronautics technical support for industry, government and the Department of Defence, including the South African National Defence Force.

This is in response to emerging opportunities, the need for local industry and companies to be globally competitive by creating world-class aeronautical products, and to decreasing South African budgets, particularly the declining Defence budget.

Likewise, it builds on CSIR Aeronautics’ success in attracting international clients to assist in filling the gap left by the great reduction in local projects. For example, it has secured European Union Research Framework Programme projects. And it has undertaken flutter testing for many of the aircraft types produced by a Europe-based major world manufacturer of general aviation aircraft.

“We have a good base in terms of aeronautic tests and evaluation,” highlights CSIR competence area manager: aeronautics systems Kaven Naidoo.

“We also have a mature world-class capability within the CSIR. We have a portfolio of test and evaluation capabilities, developed over the years, primarily in support of the Department of Defence.”

The CSIR’s facilities comprise six wind tunnels, and one water tunnel, including the largest transonic wind tunnel in the southern hemisphere. These wind tunnels allow CSIR researchers to reproduce air speeds of up to, and including, Mach 4.5, with Mach 1 being the speed of sound.

“We have provided wind tunnel testing for Saab,” he points out. “We’ve worked hard at international business development and have secured other wind tunnel tests, which will assist in keeping our wind tunnels busy for the next two years, and more international contract leads are in the pipeline.”

Inspired by major overseas aerospace research and development (R&D) institutions and departments renowned as leaders in innovation in the sector – not least, Lockheed Martin’s Advanced Development Programmes office, much better known by its now official nickname, the Skunk Works – CSIR Aeronautics Systems is seeking to anticipate technology directions that will address future needs and priorities. This, naturally, has to be done within the constraints of its financial resources.

“Low budgets are not ideal, but they do force you to optimise how you use your funds and time. It also forces creativity through partnerships,” he observes. This concept can involve developing new, necessarily niche, technologies, or developing a South African adaptation of an existing technology, in the areas of propulsion, weapons systems, unmanned aerial vehicles (UAVs), and airborne radar and electronic warfare test and evaluation systems, among others. It currently has three such projects that it can discuss in public. Other projects under way are covered by national security (not necessarily South African) and/or commercial confidentiality restrictions.

We Can Fly

In many ways, the most complicated piece of equipment on a modern jet aircraft, civil or military, is the engine. Safe, reliable and efficient jet engines require a totally integrated combination of the sciences and technologies of aerodynamics, advanced materials, mechanics, combustion and electronics (for engine control systems). Fewer than a handful of countries in the world can produce these power plants.

Most jet engines in use today are varieties of gas turbine. The development of new- generation jet engines, whether for civil or military purposes, is incredibly expensive and requires a deep national and manufacturer R&D capability. South Africa could not possibly compete in this sector – except, there is a niche. And there is real opportunity in that niche: expendable small gas turbine engines to power missiles and UAVs, especially target drones.

This is not the first time that the CSIR has been involved in such research: in the early 1990s, the State-funded Project Apartment resulted in the development and testing of a 65 kg engine, designated APA350. However, the programme was cancelled owing to budget cuts. Before that, during the 1980s, CSIR researchers were involved in a programme to upgrade and reduce the weight of the French Atar 09K50 turbojet engine. This was part of the Project Carver to develop, almost from scratch, a jet fighter in South Africa to circumvent the then United Nations arms embargo on the country. The programme involved the replacement of the original turbine blades and riveted compressor with new CSIR-developed single-crystal blades and a welded compressor. It was a technical success, increasing engine performance by 10%, but it did not sufficiently cut the weight. The programme ended with the cancellation of Project Carver in early 1991.

Today, the major original-equipment manufacturers (OEMs) in the small gas turbine engine segment are Microturbo, Teledyne and Williams International. Other companies which produce engines in this segment are Hindustan Aeronautics Limited (HAL), Mitsubishi and NPO Saturn. Of these, Microturbo is a brand of French aeroengine group Safran, while Teledyne and Williams International are US businesses, and Mitsubishi is, of course, Japanese. Their products are all subject to tight export controls to countries outside the broad Western bloc. HAL, an Indian State-owned group, is a minor player in the segment and NPO Saturn is dominant within Russia but insignificant outside Russia, except for countries using certain Russian missiles.

“There are not many engines available in this segment, and there are significant export restrictions on many of those that are currently in production,” points out Naidoo. “So, a major project being developed by our innovations team is a 800 N to 1 200 N turbojet engine for standoff weapons. It will be about 250 mm in diameter and some 500 mm in length. We hope to have the first test of the engine compressor in March 2019. Technologically, this is a major project. Such engines are critical enablers for stand-off weapons as they enable extended range applications.”

Because they would be used in weapons, such engines would be for one-off use, meaning they would not need a long lifespan. This reduces, but far from eliminates, the technical challenges posed by their development. The plan is for CSIR Aeronautics to develop the technology and the manufacturing processes to derisk both the engine and its production process. Thereafter, the expertise could be transferred to industry for commercial exploitation. Currently, this programme is being financed by the CSIR itself.

“This project could develop an entire industry,” he enthuses. “The engines may be small in size but the value of such an industry would be significant. With our approach, we will be able to go out to the market with a relevant technology. We have worked on this engine project for more than three years now. We are also in the process of refurbishing the required test facilities. The compressor tests will be a major step, and we aim to fund the development and testing of the compressor itself. The development of the engine also involves the CSIR Materials Science expertise – for example, high-quality casting.”

But the industry that could be developed from this technology might not be South African. It all depends on who is willing to invest in the project. “Foreign clients are already interested,” he reports.

Up and Away . . .

Another niche area that still offers real opportunities, and one, moreover, in which South Africa has long established and deep expertise, is the UAV, also called remotely piloted aircraft and popularly called drones. “Our aerodesign team is focused on UAVs,” reports CSIR principal aeronautical engineer and aero research group leader John Monk. “We are concerned with the more innovative design side of things. Currently, we have the Indiza hand-launched demonstrator mini-UAV, and the long endurance modular UAV (LEMU).”

It must be stressed that the CSIR is also pursuing other UAV projects on behalf of outside clients. These projects, which are funded by the clients, naturally take priority over the in-house projects. Of the in-house initiatives, the Indiza, which has a modular payload bay capable of taking images or electronic packages, is used to test sensors and electronic warfare systems, but the LEMU is the primary project. Totally funded by the CSIR, this programme is now in its third year.

The LEMU is descended from the CSIR’s Modular UAV (MUAV), through the MUAV-long endurance (MUAV-LE). Like the original MUAV, the LEMU is a twin-engined twin- fuselage design, and payloads are carried in pods mounted under the centre wing section, which connects the two fuselages. The payload pods are easily changeable, making it simple and quick to change the UAV’s mission. (The LEMU is a more refined development of the MUAV-LE, which was designed as a border patrol demonstrator, but has not flown yet.)

Two versions of the LEMU are being developed – the electrically powered e-LEMU and the internal combustion (petrol) engine-powered LEMU-IC. The e-LEMU will be the first to fly, later this year, because it is effectively complete. (Completion of the LEMUs has been delayed by the need to prioritise client-funded UAV projects.) The LEMU-IC’s airframe has been completed, but it still needs to be fitted with all its systems. It should be completed and ready to fly next year.

The two LEMU types will fulfil different types of missions. The e-LEMU, which will have an endurance of one hour, will be used for various R&D projects, especially testing different payload pods. In this regard, the great advantage of electric propulsion is that it is more reliable than petrol engines, while payload tests will rarely need more than an hour’s flying time. It will also serve to derisk the flight control system for the LEMU-IC.

The LEMU-IC is designed to fly for eight hours, while carrying a 20 kg payload. “The whole concept, again, is ‘payload pod independent’. It is going to fly at a weight of 70 kg and it has a 6 m wingspan – it is a big aircraft,” explains Monk. “We hope to get the South African Civil Aviation Authority’s approval to fly it as research aircraft. We also hope that Indiza and the LEMU will lead to commercialised spin-offs. The LEMU is . . . unique, as a civil platform, in its category. With a 20 kg payload, it could, for example, carry a compact, single-person, air-dropped life raft, as well as a camera. Or, still in the search and rescue role, the LEMUs could operate in pairs – one with cameras, the other with air-dropped life- saving gear. The LEMU can also carry Lidar (LEMU light detection and ranging – a remote sensing system used to examine the earth’s surface). Missions could be changed by simply changing the payload pod.”

“As an R&D institute that needs to deliver impact, we have to understand market requirements better,” explains Naidoo. “For this reason, we have developed several local and international partnerships with expertise from years of business in the UAV market. These partnerships can help create a commercialisation pathway. Again, this opens the opportunity for an existing or new company, local or international, to become an OEM.”

Indeed, the CSIR is currently developing a more conventional, single-fuselage derivative of the LEMU, designated S-LEMU, for a commercial client. As this is a commercial (but still technology demonstrator) programme, it takes priority over the in-house LEMU project and the first flight of the S-LEMU should take place before the end of October, ahead of the e-LEMU. No other details can currently be released.

Beautiful Balloon

From heavier-than-air to lighter-than-air flying machines, another current CSIR project is an aerostat – specifically, a wing-shaped, helium-filled, tethered balloon equipped with rigid control surfaces, developed as a surveillance platform. “Dr Ralph Katzwinkel, a vet, approached us to develop a persistent surveillance capability to help protect rhinos,” explains Monk. “He funded the initial development. We ‘brainstormed’ the idea of using an aerostat. Another partner subsequently joined us – local company Zeppelin Inflatables.”

The aerostat’s shape was chosen because it would behave better in high winds than even a blimp-shaped balloon. But, before they made the aerostat, they first studied the shape of the tether at various wind speeds; this showed that the tether was practical. “So, we decided to build an aerostat and test it.”

The success of the trials of the initial aerostat led to the construction of a second, larger one fitted with an ultraviolet protective envelope (both were made by Zeppelin Inflatables). “With this, we have run a series of tests,” he reports. “It is fitted at the rear with plastic-covered, very lightweight carbon fibre control surfaces. With this second version, we have demonstrated a low-cost autopilot, mounted on the aerostat, which controls it in pitch, yaw and roll. We also have a load cell on the main tether to keep the load on the tether safe, so it cannot snap. No proper payload has been tried yet, but that will be the easy part, as there are lots of tested and proven payloads available. The difficult bit is ensuring controllability. The autopilot software is open-source and we have modified it to meet our requirements.”

This programme is still very much alive, but needs further funding. This is because the next step will be to build a yet larger, more robust aerostat, as well as all the necessary support equipment, including a ground transport trailer, a winch and so on. This would be a preproduction version for field trials. Again, this is a niche area with global market potential.

“‘Aeronautics innovation’ is also concerned with developing postgraduate students,” stresses Naidoo. This involves supporting postgraduate students undertaking research in various high-technology areas of aeronautics. Thus, one master’s student is examining a topic that has the potential to revive ram jet technology in South Africa. (Ram jets are the simplest form of jet engine, with no moving parts, but need to be moving at high speeds to function effectively; today, they are usually used to power long- range air-launched missiles; South African previously had ram jet technology.) Another PhD student is examining the possibility of novel – the tech- nology does not yet exist – guidance and control for weapon systems.

“Using postgraduate programmes in this way means we inspire young individuals while investigating and reviewing technologies, capabilities and potential at reduced cost,” he highlights. “Our next target for a PhD? – urban air mobility (passenger-carrying autonomous air vehicles).”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation