Coperion and Coperion K-Tron to Exhibit at the International Powder & Bulk Solids Conference & Exhibition, Rosemont,

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Coperion and Coperion K-Tron formally announce exhibition at the International Powder & Bulk Solids Conference & Exhibition, Donald E. Stephens Convention Center, Rosemont, Illinois, May 3-5 – Booth 1413. The booth will feature feeding, pneumatic conveying and systems engineered solutions for various processing applications in the food, pharmaceutical, plastics and chemical industries.

The booth will display a new compact stainless steel rotary valve ZZB which was developed for small capacities and high sanitary needs. The interior and exterior polished surfaces prevent undesired product deposits. With the standard extraction device, the rotor can be easily removed from the housing. Easy to open tri-clamp flange connections at both inlet and outlet simplify installation and maintenance. The ZZB is available in two sizes: 80 mm [3 in] and 100 mm [4 in] (inlet and outlet) and is suitable for use in ATEX zones.

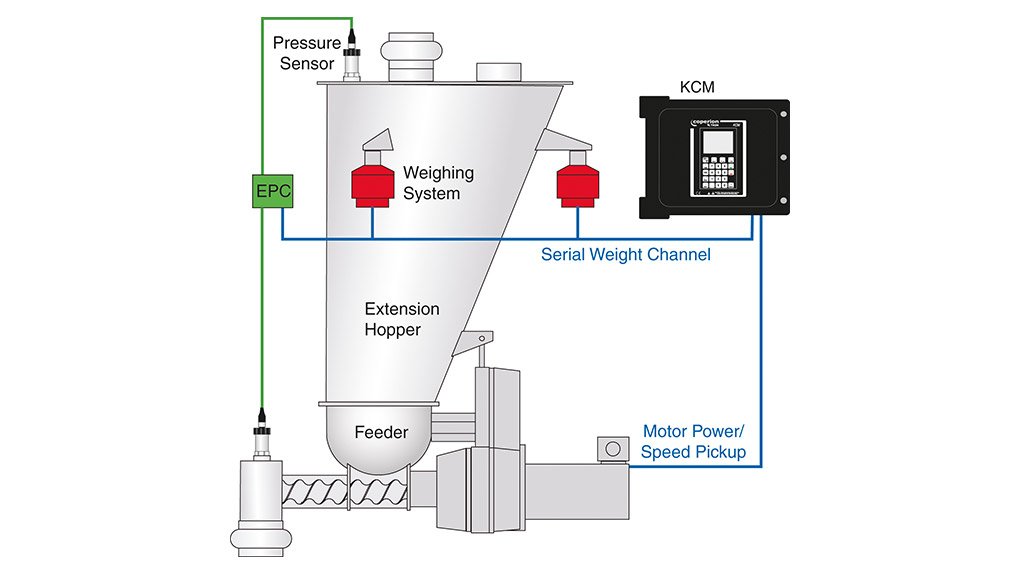

Debuting at the Powder Show is our newest development – the Electronic Pressure Compensation System. This system is designed for high-accuracy Coperion K-Tron loss-in-weight feeders. Coperion K-Tron has developed a clever but simple electronic solution for accurate and steady pressure compensation in feeder hoppers. The modular design incorporates pressure sensors and electronics tailored to interact smoothly with Coperion K-Tron’s KCM feeder control system. Retrofitting options for existing feeders are available. EPC can be installed on a majority of Coperion K-Tron gravimetric feeders in almost any application and all industries.

The Coperion K-Tron Dense Phase Demo System featuring transparent tubing will be a highlight to the booth since it will allow booth guests to see firsthand how dense phase conveying works. The Dense Phase System will be constructed to allow guests to watch particle flow through this unique and one-of-a-kind system. See for yourself how dense phase conveying is especially suitable for premixed materials, materials with high bulk density, materials which are abrasive, friable, or tend to segregate.

Also on display will be the Coperion ZRD Hygienic Rotary Valve. This valve is specially designed for sanitary, pharmaceutical, food and chemical applications where contamination is a constant concern, and frequent disassembly and cleaning is required. The ZRD Hygienic includes full access extraction system and a large inlet for high filling efficiency. Without removing the valve from the system, the ZRD Hygienic can be easily disassembled, cleaned and reassembled. The ZRD Hygienic is designed according to EHEDG guidelines with pressure differentials up to 1.5 bar [21 psi] and temperatures up to 100°C [212°F].

Another valve on display will be the Coperion WYK Diverter Valve which is ideal for powders and granular products. The asymmetric design with 45° angle, is suitable for distributing and collecting in pneumatic conveying lines and in gravity pipes and is ideal for sanitary and wet cleanable design, EHEDG certified (0.8 Ra execution); suitable for the wet cleaning process. It is essential for the function and for the cleaning result that the rotor is disassembled after each washing process and manually cleaned and dried.

The booth will also display the Sanitary Filter Receiver (SFR) which provides automatic separation of product material from the convey air for vacuum and pressure conveying in sanitary applications, for batch and continuous processes. The SFR is specifically designed for stringent food applications requiring quick clean-out and to reduce food contaminants and/or the cross contamination of allergens. The unit is easily cleanable with round corners, no ledges and no hidden areas.

A single to twin screw Quick Change Feeder will be available for booth guests, too. It is designed for applications requiring quick changeover of materials and convenience of fast cleaning. The QC feeder allows for the removal of the entire feeder module with screws in place, to be replaced with a second unit. The removed feeder module can then be transported to a cleaning facility for further disassembly and cleaning before being prepped for another material. In loss-in-weight feeding applications where difficult flowing or cohesive materials form rat-holes or bridging in the hopper, K-Tron’s new ActiFlow flow aid eliminates the need for mechanical agitation, greatly simplifying the cleaning process.

Lastly, the HD Aerolock Rotary Valve will be displayed. It’s engineered for heavy duty industrial service and high volumetric efficiency at up to 1.0 bar [15 PSI] pressure differential. The HD conveys a broad range of products in the plastics, chemicals, minerals and food industries. The HD Aerolock is used to handle pellets and granular products, and will meter powder materials at over 100,000 lbs./hr.

Experts from Coperion K-Tron and Coperion will be on hand to answer all of your questions.

For complete show highlight, visit www.coperion.com

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation