Concept Laser will be showing innovation on all levels at formnext powered by TCT

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

- Sales launch of the new machine architecture

- Innovations in the small and large machine segment

- Expansion of the range of materials announced

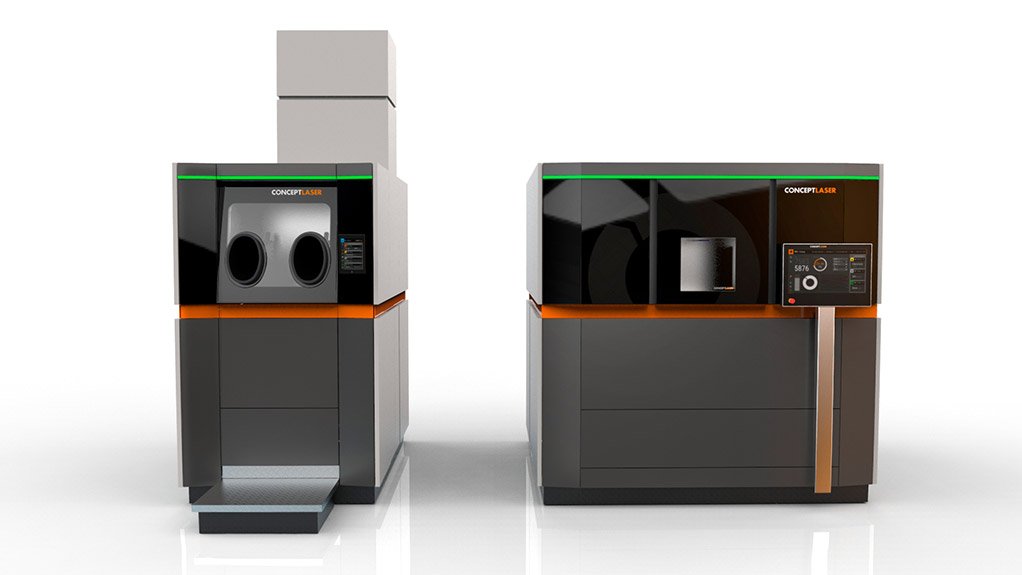

The AM scene awaits the second edition of formnext powered by TCT in Frankfurt a. Main (November 15-18, 2016) with great excitement. It is already becoming increasingly apparent that formnext powered by TCT is the new leading trade fair for 3D printing in Europe. It is therefore appropriate that Concept Laser, the pioneer and technological leader of the powder-bed-based laser melting of metals, will be presenting its innovations at Stand F48 in Hall 3.1. The sales launch of the new machine architecture is awaited with great anticipation.

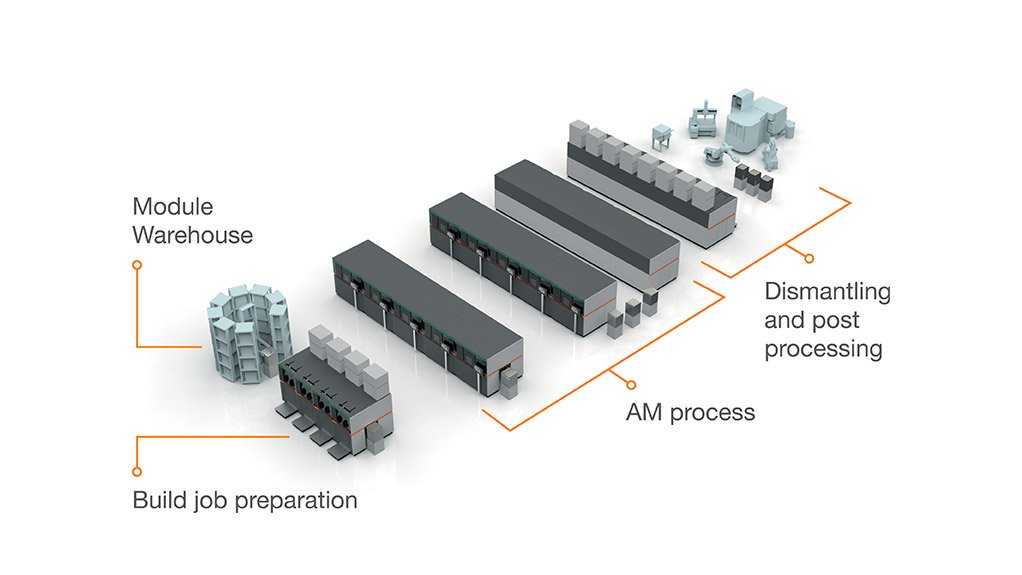

Every detail of the new machine concept with fully modular machine technology along with the series production scenario of the “AM Factory of Tomorrow” that lies behind it will be presented to the public at the trade show. In addition, Concept Laser will present innovations in the small and large machine segment and unveil a significantly expanded range of materials.

Concept Laser is not yet revealing any of the specific content. Oliver Edelmann, Vice President Global Sales & Marketing, says: “In October, shortly before formnext powered by TCT, the LaserCUSING users will be congregating for our customer event in Bamberg. For understandable reasons, we want to provide our group of users with exclusive advance information about these innovation before we turn our attention to the wider public in Frankfurt. But you can rest assured that this year we will once again have numerous innovations to show. ”

Overview of trade fair highlights

The clear focus for Concept Laser is on the commercial launch of the new machine architecture and the series production scenario of the “AM Factory of Tomorrow” that lies behind it. Digitization, interlinking and a high degree of automation, reflecting the basic idea of “Industry 4.0”, will all be consistently implemented. But there will also be new things to see in relation to the small and large machine segment. This relates to both the machine technology and its periphery. In terms of materials, several new materials will be unveiled.

There will also be detailed information about the QM Meltpool 3D quality assurance tool, which was presented with the “International Additive Manufacturing Award” in March of this year. Information islands will add the finishing touch to the trade show presentation by the company from Lichtenfels. They will address issues such as quality assurance, design that suits the process, topology optimization and examples of products from the fields of bionics and lightweight construction, and encourage you to talk to the AM practitioners. In addition, machines from the small and medium-sized segment as well as the new machine architecture will be on display for you to see.

New machine architecture as the next milestone

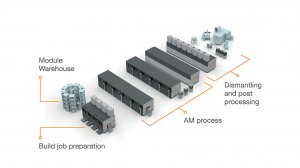

The next milestone for Concept Laser will be the commercial availability of the new machine architecture, which is based on the concept of the “AM Factory of Tomorrow”. In future, there will be stand-alone process stations for the build process with a build envelope of 400 x 400 x >400 mm³ which will have 1 to 4 laser systems featuring multilaser technology with 400W to 1,000W laser sources. There is also a new 2-axis coating process allowing the return run of the coater to be performed alongside the exposure. This results in a considerable time saving during the coating process. An automated tool changing system, as is the case with CNC machine technology, also promises a high level of flexibility, time advantages when setting up the machine, and reduces the level of manual intervention by the operator.

For set-up and disarming processes, there are physically separate, autonomous handling stations. This enables “optimum use windows” right through to the ideal of 24/7 availability of the machine technology. An automated material flow is another unique selling point. This allows self-contained modules for transport and material provision to be used on the process stations. This and the decoupling of the process and handling stations simplify each production assignment.

In parallel rather than sequentially: This basic idea behind the new machine architecture from Concept Laser results in an increase in availability and downtimes kept to a minimum. But the basic concept of the “AM Factory of Tomorrow” does in fact go beyond this approach and also envisages linking up with traditional manufacturing methods, e.g. in the post-processing of the components. The realization of the key idea of “Industry 4.0” and the machine solution which users have asked for to allow the economical series production of metallic parts are being consistently implemented. Oliver Edelmann says: “With the new machine architecture and the concept of the “AM Factory of Tomorrow” that is associated with it, Concept Laser will once again set a milestone in the additive manufacturing of metallic parts. Our new approach explores completely new avenues and enables economical series production.”

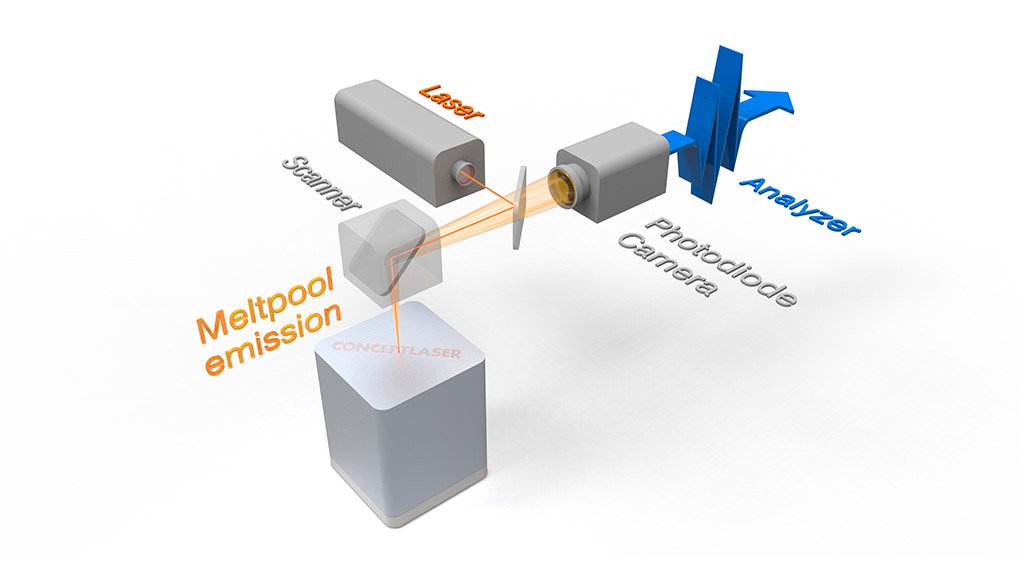

In-situ process monitoring with QM Meltpool 3D: Pioneering role when it comes to quality assurance and monitoring

In-situ process monitoring has been one of the key strategic fields of technology for Concept Laser since as early as 2004, long before the market was demanding such a solution.

This far-sighted approach resulted in the development and market launch of QM Meltpool 3D, the first process monitoring tool of its type which received the “International Additive Manufacturing Award 2016” (IAMA) at Metav 2016. QM Meltpool 3D provides quality-relevant data for process monitoring and documentation in real time, and this is absolutely essential for part manufacturing and qualification in particular for the aerospace and medical technology sectors. The system records positional characteristics of the meltpool while the part is being created.

This data can be visualized on a three-dimensional map and analyzed by the user. According to the manufacturer, this analytical tool is comparable to the HD resolution of computed tomography (CT). The tool also saves time and money compared to conventional component testing. But the practical added value provided by this innovation is not just an original tool for active quality assurance. In manufacturing, build jobs can be optimized through iterative variation of the parameters. Support structures can be adapted and in particular the upstream part structure can be designed to be easier to fabricate. Not least new opportunities are emerging in material research.

Verdict

This year, visitors can once again look forward to seeing lots of innovation at Concept Laser’s Stand F48 in Hall 3.1. These will include in particular a considerably expanded range of materials, new products in the small and large machine segment and of course the commercial launch of the new machine architecture. Additional information islands will report on numerous other projects and thus once again promise to deliver a highly attractive trade show appearance by Concept Laser.

Oliver Edelmann says: “We are anticipating formnext powered by TCT with great enthusiasm and are very much looking forward to being able to present lots of innovations to the public at the trade show. This year Concept Laser will once again champion its role as a leading innovator that demands the highest quality standards. Come along and see for yourself; we look forward to meeting you!”

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation