Business Unusual: Embracing Disruptive Technologies in the Automotive Sector

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Rapid technological advancements in the global manufacturing landscape have changed the ways in which manufacturers function – from product design and development, to production optimisation, to techniques selected to penetrate new markets and deliver products to customers.

Interest and investment in disruptive technologies have increased significantly in recent years, with a handful of local firms in the automotive sector embracing these technologies. Shatterprufe is one of these companies. Located in the automotive component manufacturing hub of Port Elizabeth, it is the only local automotive glass manufacturer which has the capability to supply the global automotive Original Equipment Manufacturers (OEMs) assembling vehicles in South Africa.

With four million pieces of glass being manufactured annually, with an almost equal revenue split across the three markets of OEM, local aftermarket and the export aftermarket, Shatterprufe is in a unique position to pursue advanced manufacturing technologies to optimise their product development and manufacturing processes.

Dave Coffey, Managing Director of Shatterprufe and National Association of Automotive Component and Allied Manufacturers (NAACAM) President, is one of these early adopters. “For Shatterprufe, it is critical to get to the aftermarket early with new products that comply with the stringent quality standards of the OEM’s”, explained Coffey.

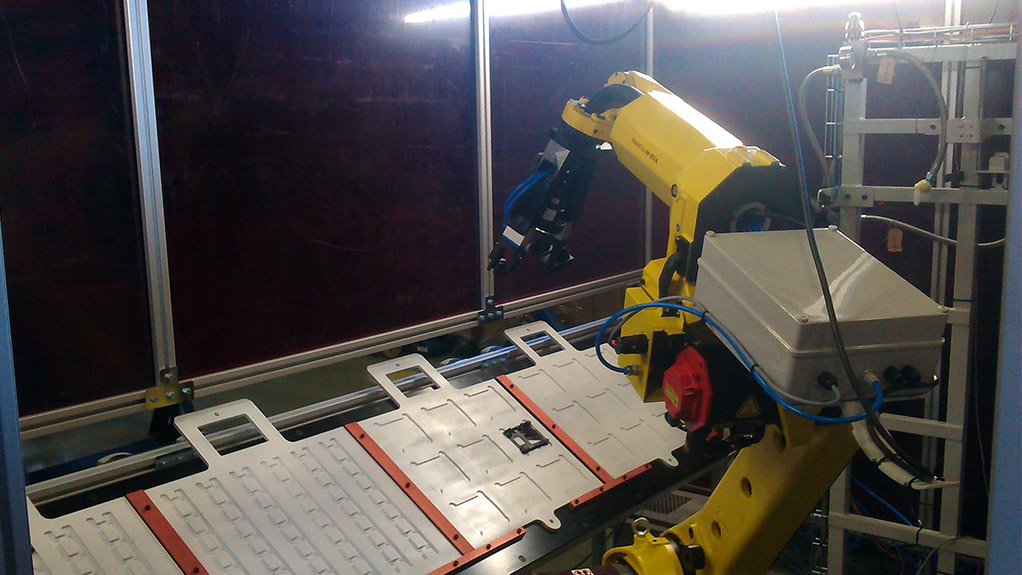

Typically, Shatterprufe will buy an OEM product in Europe, should the vehicle not be sold locally, bring it to South Africa, develop the computer aided design (CAD) drawings, and then produce the part which will then be sent to the international client for approval. Through exploring new scanning technologies, Shatterprufe will receive a 3-D scan of the product, convert this into a CAD file and commence development and manufacturing; this could include the 3D printing of the checking fixture.

Then, the developed part will be scanned and sent to the client for approval. For Shatterprufe, this technology can minimise the sample delivery time by four to six weeks. “We can reduce substantial time in the product development process and therefore reduce lead times to market significantly. We are also prototyping and using this scanning technology for sample approval of components for glass as well.

We expect to see a full roll-out of this technology by the end of 2019”, said Coffey. He explained that the key advantage provided by the technology is that it allows his company to get to the market first, and to secure both the local and export aftermarket volumes.

The South African Automotive Masterplan (SAAM) includes ambitious growth targets for the sector over the medium- to long-term. Some of this growth will result from the investment in these advanced manufacturing technologies, explains Coffey. “I can foresee these technologies facilitating competitiveness which will enable the growth we need”, said Coffey. He suggests that as organisations are always looking for opportunities to grow, and if these technologies are relevant and provide clear benefits, then the industry will willingly embrace them.

From his experience, he found that people generally embrace technologies once they have seen them being demonstrated, where the technical merits of the technology are clearly outlined. However, and more importantly, the benefit of partnering a client in developing new technology should not be underestimated.

To support this, in 2019, the NAACAM Show will introduce an innovative approach to profiling automotive technologies and innovations through the hosting of technical demonstrations. For the first time, exhibitors will have the opportunity to host 20-minute technical demonstrations in the NAACAM Show’s purpose-built Media and Demonstration Centre.

Automotive component manufacturers and technology partners will be encouraged to present a case study or conduct a demonstration on a key technology or innovation which supports the NAACAM Show conference themes, with an explicit focus on the future of manufacturing in the automotive sector.

This will be followed by an informal question and answer session where delegates will have the opportunity to seek clarity or advice on the technologies, for their own operations. “These tech demos will provide unique insight for component manufacturers to gain access to practical, hands-on examples of innovative technologies, as well as provide a platform to stimulate a dialogue around integrating technology into the automotive sector”, said Coffey.

The NAACAM Show is scheduled to take place from 12-14 March 2019 at the Durban ICC, and more information can be found at www.naacamshow.co.za

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation