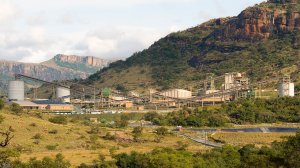

Bulk Merensky sampling on way at Northam Platinum’s Booysendal

BOOYSENDAL (miningweekly.com) – Tenders are expected to be invited next week for the bulk sampling programme that forms part of a study into the economic feasibility of mining the Merensky reef as part of a potential future expansion drive at Northam Platinum’s new Booysendal mine, where only upper group two (UG2) reef is currently being mined.

The prefeasibility study is aimed at proving that the narrower Merensky reef, originally earmarked for conventional mining, can be mined using the same mechanised bord-and-pillar mining method that is being successfully implemented on the UG2 horizon, and that the bulk sample can pass the metallurgical tests, given that the Merensky material will be of lower grade.

“We need to ensure that we can still get high recoveries against a lower-grade product by designing for the dilution,” Northam Platinum CEO Paul Dunne explained to Mining Weekly Online.

Mining the UG2 reef using the mechanised bord-and-pillar method has delivered a world-class safety performance, which Northam would like to see replicated on the Merensky horizon, should the proposed new project be given the go-ahead.

“The biggest safety differentiator is without question the mining method,” Dunne said.

Booysendal’s UG2 operation is expected to be producing at a rate of 160 000 oz/y before the end of 2015 and Northam management sees merit in the proposed Merensky project benefitting from the UG2 mine’s same fleet of equipment and same skillsets.

Although the wider UG2 reef lends itself to mechanised mining method more than the narrower Merensky reef, Northam does not believe that the Merensky reef should be mined conventionally.

“We think we should keep the mining methods consistent and we believe we can do that by accepting dilution on the Merensky. If the metallurgists know what’s coming, they can design the plant accordingly. So that’s our preferred route, mechanised mining producing a high volume and lower-grade product,” Dunne added.

The site demarcated for the bulk sampling and potential boxcut is close to one of several historical adits developed by geological pioneer Hans Merensky, who discovered platinum nearby nearly 90 years ago.

“We identified those historical adits when we built the UG2 mine here and we aim to preserve them,” Northam Platinum project manager Rene Rautenbach added to Mining Weekly Online.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation