Babcock adopts Lean Retail System

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

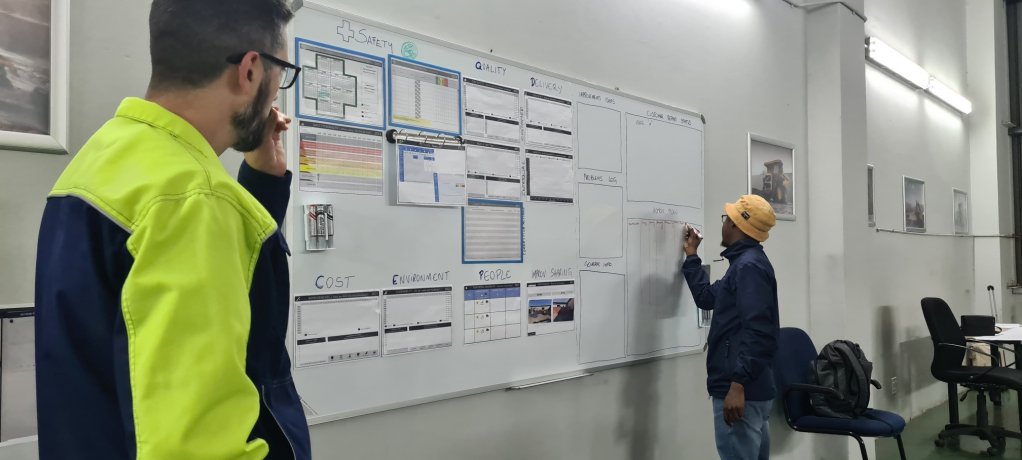

Babcock has become the first Volvo Construction Equipment (Volvo CE) dealer in the world to adopt Volvo CE’s Lean Retail System – a programme guided by a set of principles aimed towards developing a culture of constant improvement and problem solving. The company is currently busy with the pilot roll out at its Bartlett, Jet Park operations

Championed by Volvo CE, the Lean Retail System is aimed at cultivating a culture of continuous improvement by identifying different parts in the work process that can be optimised to make them easier, faster, better, cheaper and less stressful, and improve them, on a continual basis.

Duncan Gooch, Head of SHEQ – Equipment at Babcock, explains that the programme is premised on the same foundations as Lean Manufacturing, a principle which originated in Japan and is designed to minimise the waste of material and labour while maintaining or increasing levels of production.

“The Lean Retail System entails continual identification of opportunities to improve processes, increase efficiency and reduce waste – both in terms of time and resources. Ultimately, it is about eliminating that which does not add value and delivering the best possible service to the customer as quickly and cost-effectively as possible,” explains Gooch.

Continuous improvement, stresses Gooch, is not about making drastic changes, but small improvements on a constant basis. Continuous improvement, especially in the form of small adjustments, is one of the original lean principles. The smaller improvements are usually quicker, involve less to no cost, do not require a specialised team, the latter meaning anyone can play a role in the process. If something doesn’t work, the team can take a small step back, learn from it and continue moving forward.

Babcock commenced the rollout of the programme on September 4, 2023 – becoming the first Volvo CE dealer to do so – under the guidance of four Sweden-based experts from the OEM. During the first day of the programme, the Babcock management team was exposed to the fundamentals of the lean principles in retail.

During the following four days, the Volvo CE team spent time with the operational workshop-based pre-delivery inspection (PDI) team and Gooch, who initially headed the project before the appointment of a dedicated graduate trainee who has been tasked to drive the programme. An area of initial focus is the PDI section of the business, where Babcock is looking at the current processes and identifying opportunities to make them more efficient and to reduce waste.

“Adopting the lean principles in our PDI environment is going to be a six-month process, working closely with Volvo CE. Until March 2024, three of the four Volvo experts will visit us every month for three days at our premises, following up on progress made and providing guidance where necessary,” says Gooch.

In addition, there is a scheduled ‘Teams call’ every week between Babcock representatives and the Volvo CE experts for regular updates and guidance. “We have already identified several small process steps which need improvement in our PDI section. Each member of the team has acknowledged some issues within their area of responsibility that they can improve on,” concludes Gooch.

After the initial six-month focus on the PDI section under the guidance of Volvo CE, Babcock will look to independently roll out the lean principles to other areas of the business. “Ultimately, it is about planting the Lean culture of continuous improvement in all aspects of our business. Buy in from all stakeholders – staff and management – is critical for the sustained success of this programme. The intent of ‘lean’ is to have everyone instinctively making small continuous improvements, everywhere, all the time,” concludes Gooch.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation