Aury Africa offers value-added screening service for coal sector

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

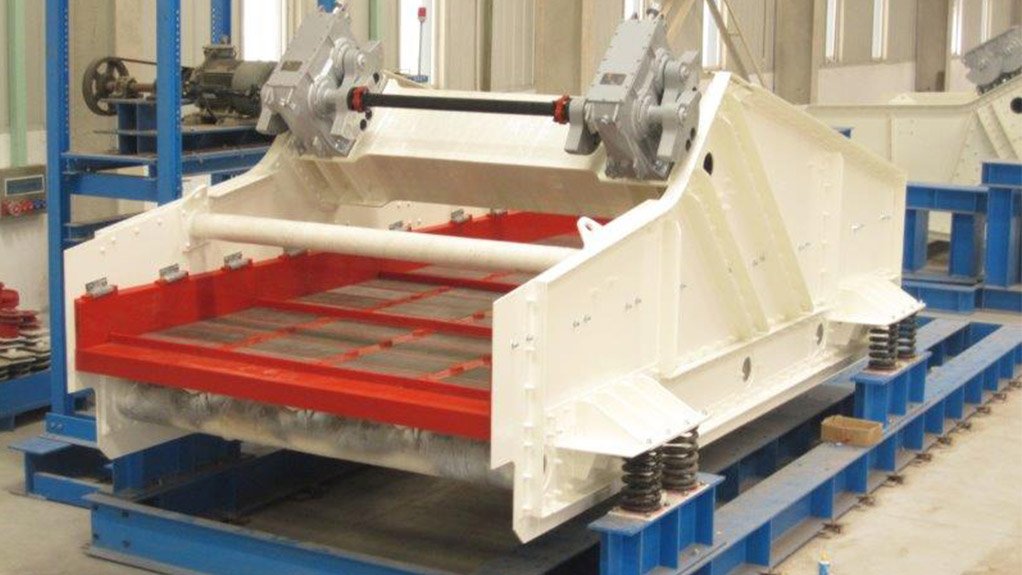

Innovative screening and vibrating equipment solutions and services provider Aury Africa can advise coal-plant operators on the correct screen size to maximise operational efficiency, coupled with comprehensive aftermarket support to assist with all proactive maintenance requirements.

The manufacturer produces a complete range of high-quality vibrating screens for the coal and minerals-processing industries. Banana vibrating screens are available in single- and double-deck configuration, from 1.8 m x 4.8 m up to 4.8 m wide and 8.5 m long.

Horizontal vibrating screens are available in single- and double-deck configuration, from 1.2 m x 2.4 m up to 4.3 m wide and 8.5 m long. High-frequency vibrating screens are available from 0.9 m x 1.8 m up to 2.4 m x 3.7 m.

Circular motion vibrating screens are available in single- and double-deck configuration, from 1.8 m x 3 m up to 3 m x 6.1 m. Flip flop vibrating screens are available in single-, double- or triple-deck configuration, from 1.5 m wide up to 12 m long.

Aury Africa is also able to supply a range of exciters to fit most OEM screen types. Consumable products available include intertank/interstage cylinder screens for classification, sieve bends and static panels for separation, and centrifuge baskets.

“The fact that we can access technical expertise from our international group is a major advantage for our customers, as we have extensive experience coupled with expertise, due to having worked with vibrating equipment in the mining industry for many years,” Aury Africa Director Sydney Parkhouse comments.

Another major benefit for local coal-mining customers is that Aury Africa can provide bespoke solutions, in addition to having a standard equipment range. “We have an in-house design capability, and can even undertake research and development in order to be able to cater for specific requirements and applications,” Parkhouse notes.

While the mechanical principles of vibrating screens are well understood, there are numerous variables that need to be taken into account, especially with diverse applications such as dewatering. Perhaps the most important criteria is robustness, where local manufacture is important in guaranteeing the best quality and longest service life possible, especially for the large-tonnage outputs in the coal-mining industry in particular. In addition, local manufacture also lowers the total cost of vibrating and screening equipment significantly, compared to imported equipment.

Vibrating-screen aperture sizes need to be calibrated carefully depending on the type of raw coal being processed, Aury Africa Business Development Manager George Sturgeon points out. This is especially important for coal being supplied to electricity utility Eskom, for example, which has specific quality standards for power-generation purposes.

Vibrating-screen equipment used in the construction industry, on the other hand, needs to be sufficiently robust to be able to process aggregates produced by drill-and-blast methods, for example. This results in a lot of material that falls outside the required specification that still needs to be screened efficiently.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation