Atlas Copco’s AutoDrill 2 - automated drilling at its best

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

“Mines that keep abreast of and implement the latest cutting-edge technology today are the mines that will still be around tomorrow,” says Regional Business Line Manager for Atlas Copco Drilling Solutions, Heino Hammann.

“State-of-the-art technology is incorporated into both hardware i.e. machinery and equipment, as well as into software programmes developed to optimise the capabilities of these machines. Enter automation technology which alongside improving machine performance, upskills operators and improves safety and productivity, ultimately drives up profitability which is paramount to a mine’s sustainability. It is therefore our principal goal to develop sustainable solutions that will contribute to more efficient and cost effective mining operations.”

One such solution is the new AutoDrill 2 automated drill system from Atlas Copco Drilling Solutions. Specially developed to enhance the entire drilling process and production stream, the AutoDrill 2 offers a game changing solution for Pit Viper automation and blasthole drilling.

This next generation patent-pending drill system is the smarter sibling of the original AutoDrill, an auto drilling system with the capability of completing the hole with a touch of a button. Since its introduction by Atlas Copco Drilling Solutions a few years ago (2008), the first generation AutoDrill has been deployed on literally hundreds of Pit Vipers, drilling millions of meters around the world in a multitude of applications.

“Mines that have successfully installed automated blast hole drilling techniques report improved productivity and high level performance from their drilling fleets,” states Hammann. “Better planning and higher quality blasts have an enormous positive impact on the entire mining process adding value both up and downstream.”

The success of AutoDrill in revolutionising the global blast hole drilling industry combined with the ongoing development for automated Pit Vipers through the Rig Control System (RCS) prompted the development of the AutoDrill 2.

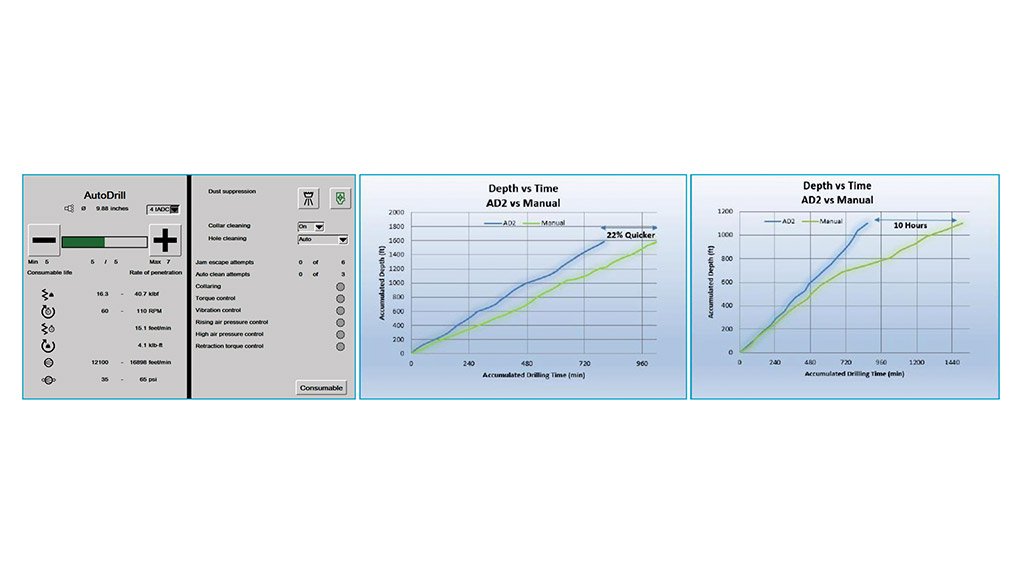

“Fitted with AutoDrill 2, our Pit Vipers function 22% faster than a manual human-operated rig,” affirms Hammann. “Equipped with the very latest modern technology, the AutoDrill 2 delivers better production efficiency, repeat-ability, consistency and stability, basically consistent overall improved drill hole quality.

Additionally, excellent blast fragmentation improves load- and crush-ability which contributes to huge savings. Reductions in operational costs and improvements in productivity enable plants to operate at maximum capacity, adding to the bottom line.”

The design of the AutoDrill 2 incorporates all the experience and knowledge gained from developing the Pit Viper drills and ground engaging tools. By matching the power of the Pit Viper drill, the capability of the bit and the intelligence of listening to the ground through proprietary algorithms, unparalleled hole quality is maintained from collar to cleaning.

According to Hamman AutoDrill 2 was developed in conjunction with the Atlas Copco’s Rock Drilling Tools division to ensure it complemented the rig and its consumables’ physical capabilities. “The result of this joint development ensures high penetration rates without sacrificing bit life leading to reduced overall drilling costs.” The drill system’s revolutionary performance has rewritten the drilling rulebook delivering speed, quality and consistency - hole after hole, shift after shift.

In addition to improving performance, another primary objective behind the design of the AutoDrill 2 was to provide a simple and intuitive setup process. “The AutoDrill 2 can be considered as the adaptive cruise control of the drilling world,” explains Hammann. “As the control system basically does all the work it is extremely simple and easy to use and does not require high knowledge or experience levels.”

Hammann confirms that customers who are operating the first generation technology can easily upgrade to AutoDrill 2 which can be fitted to any single pass Pit Viper with RCS 4. Atlas Copco Drilling Solutions’ other automated system technologies including optional HPGPS capabilities (pre-planned holes location to improve hole accuracy and reduce setup time) and AutoLevel (reduce setup time level at each hole with a touch of a button) can also be retrofitted to Atlas Copco’s in-house developed Rig Control System (RCS).

Alongside technical support, Atlas Copco also offers on-site operator and technical training; correct operation of the machine and AutoDrill 2 will ensure utilisation of the machine to its full capabilities automated drilling at its best.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation