Atlas Copco portable dewatering pumps are tough!

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

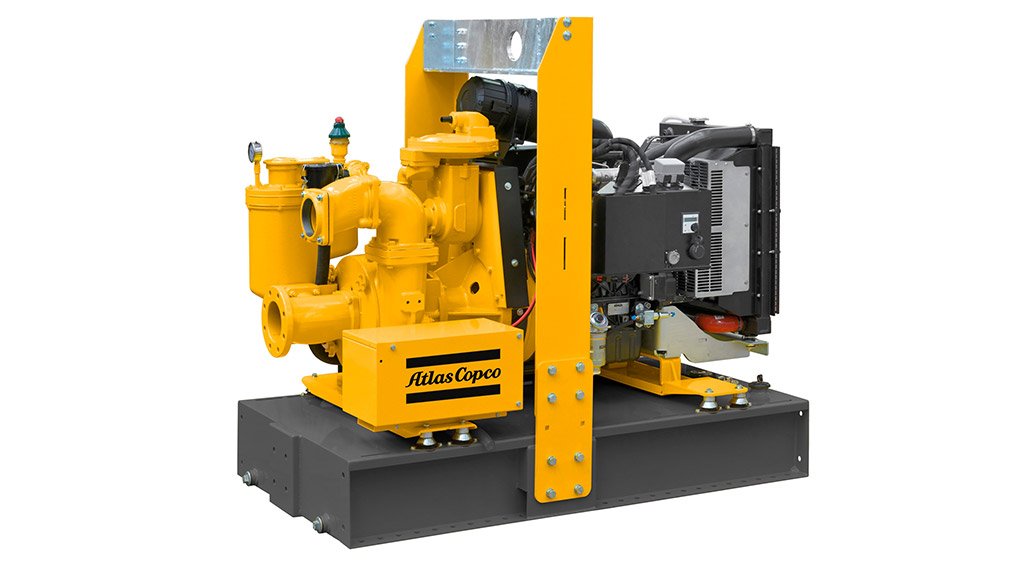

High performance, class-leading fuel efficiency and complete portability underpin the PAS range of centrifugal diesel-driven open-frame dewatering pumps from Atlas Copco Construction Technique’s Portable Energy division.

The development of the PAS range is centred on vital information gained through Atlas Copco’s close working relationship with construction customers around the world for over 140 years. “This latest eighteen open-frame additions to our pump portfolio supports our ever popular PAS dry prime canopy version with flow capabilities of up to 590 m3/h,” says David Stanford, Portable Energy Business Line Manager.

The fully portable PAS open-frame units are ideal for sites with no access to a power source and include both wet- and dry-prime options. The dry-prime variants offer rapid priming time and higher capacities and are suited to applications where there are solids in the liquid. Stanford explains that the setting of the mechanical shaft seals in an oil bath gives the pumps their dry running capability without the risk of damage to the shaft seals.

“These pumps are therefore ideal for intermittent flow applications or when there is a danger of running dry during long periods of continuous operation. The wet-prime pumps offer a cost-effective solution for applications where there is a consistent flow.

The PAS open-frame system comprises a centrifugal pump, a semi-open impeller for easy handling of solids of various sizes without the risk of clogging and a large separator which enables the air to be separated from the liquid and sucked by the vacuum pump, making automatic priming possible. Even with suction heights of several metres, the rapid evacuation of air from the suction pipe ensures fast activation of pumping.

The modular design of the PAS range allows many different configurations that meet multiple applications, from ground water dewatering on construction and mining sites, drainage of reservoirs, canals or ponds, solids removal and sewage bypass to naval platform ballasting and emergency situations such as flooding.

With a wide range of sizes, a discharge size ranging from 3inch to 8inch and performance levels from 105 m3/h to 630 m3/h, the pumps provide efficient solutions for virtually any dewatering application and flow level between these two points. The range starts with the 6.4kW PAS3 wet-prime pump; with a maximum flow capacity of 120m3/h, a discharge size of 3inch, a maximum head of 24.5m and some 4.5 hours of fuel autonomy, the PAS3 is capable of handling solids of up to 40mm. Solids of up to 76mm are no match for the top of the range dry-prime PAS8 which operates at a head of up to 30m, offers a discharge size of 8inch and boasts a maximum flow of 630m3/h.

Additional features and related benefits of the PAS range include a high efficiency hydraulic end for reduced fuel consumption and a high capacity diaphragm pump for automatic priming. The open-frame design offers easy access to all components for fast, straightforward servicing and maintenance.

“Our pump portfolio is a perfect fit to our forward-thinking philosophy and value proposition,” notes Stanford. “Through constant development we aim for manufacturing excellence in order to provide more compact, lightweight products to facilitate fast easy portability and ever more reliable and efficient products that are good for the environment and contribute to sustainable productivity for customers.

Finally, we support our customers with quality service as well as expert after-sales service from our team of qualified and skilled technicians to optimise product functioning for maximised uptime and productivity and lowest operational and ownership costs.”

A range of portable, powerful and efficient electrical submersible WEDA pumps which manages flows from 225 to 16.500 litres per minute with a maximum head of 85m completes Atlas Copco Portable Energy’s comprehensive dewatering pump solutions.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation