Amid growing water worries, desalination option enters SA’s supply debate

Scarce surface water resources in South Africa are threatening the availability of potable bulk water, which is also coming under strain because of growing suburban areas and increased demand from consumers. The recycling of wastewater to ensure long-term sustain- ability has been posited as the most inexpensive and feasible solution, being faster to implement than desalination.

South Africa is mostly a semiarid environment. This means that, prior to any form of human consumption and demand for fresh water, the resource is already in a state of insecurity. During extraordinary weather patterns, such as dry spells during periods of lower-than-average rainfall or prolonged droughts, surface water becomes constrained.

The recent drought that affected Gauteng underlined the importance of focusing on water sustainability and having additional means of abstracting water from other sources.

However, the drought currently affecting the Western Cape highlights the imprudence of relying on surface water in a region bordered by a vast coastline, with a seemingly endless supply of water, but which is unsuitable for human consumption.

Water fragility and sustainability issues have increasingly foregrounded desalination, which refers to the removal of salts and minerals from water. Desalination technology can transform undrinkable sea water into a sustainable freshwater resource that can be exploited even during the worst droughts. With as much as 97% of water on earth contained in the oceans, and the remainder in rivers, lakes, glaciers and ice, desalination is gaining ground as a possible solution.

CASE FOR DESALINATION

Johannesburg-based water treatment company Veolia Water Technologies business development manager Chris Braybrooke says desalination technology comprises thermal and membrane-based filtration, with the latter also referred to as reverse osmosis (RO).

Veolia Water Technologies is the water division of France-based environmental solutions company Veolia Environment. The division is the largest desalination solutions provider in the world in terms of total worldwide installed capacity: 6.75-million cubic metres of desalinated water a day (these are all RO-based plants, including those processing normal inland water).

Thermal desalination entails boiling raw water and subsequently purifying it through the condensation gathered from the resulting steam. The technology requires very high energy consumption to operate, making it “irrelevant” in South Africa, owing to constrained power infrastructure, states Braybrooke, adding that thermal desalination is used only in countries with very cheap, or free, energy, such as most oil-rich countries. Thermal desalination infrastructure is also more expensive to build than that required for RO technology.

RO technology would not only be economically more feasible to implement, but also cheaper to operate in South Africa.

RO systems employ an array of cylindrical membranes through which preconditioned water is fed at high pressure to remove salts and other impurities. Seawater desalination using RO requires higher pressures than the desalination of inland, and less salty, sources of water, making such desalination a cheaper option to produce potable water, as it uses less energy.

In addition, purified water recovery is much lower at the coast than inland, as inland applications discharge less brine, owing to the salt content for inland water being lower. For seawater processing, Braybrooke says, the average recovery rate is 40% desalinated water, while 60% is discharged as brine back into the ocean. Much greater efficiency can be achieved using RO technology for inland water, with a recovery rate as high as 90% of purified water.

Braybrooke notes that sea water differs in its composition at different locations along the coast, and that an RO plant must, therefore, be customised to operate accordingly.

Implementing an RO plant is “simple” and can start with a technical study, he says, adding that, with client approval and at a client’s request, construction can begin with a small-scale pilot plant, developing to a full-scale plant.

Modular RO plants are very popular in South Africa, says Braybrooke, explaining that the response time to commission such a plant is significantly faster than that of a full-scale plant. “With modular systems, we do not have to reinvent the wheel – they are designed and built according to predetermined specifications and can be used in an array of applications.”

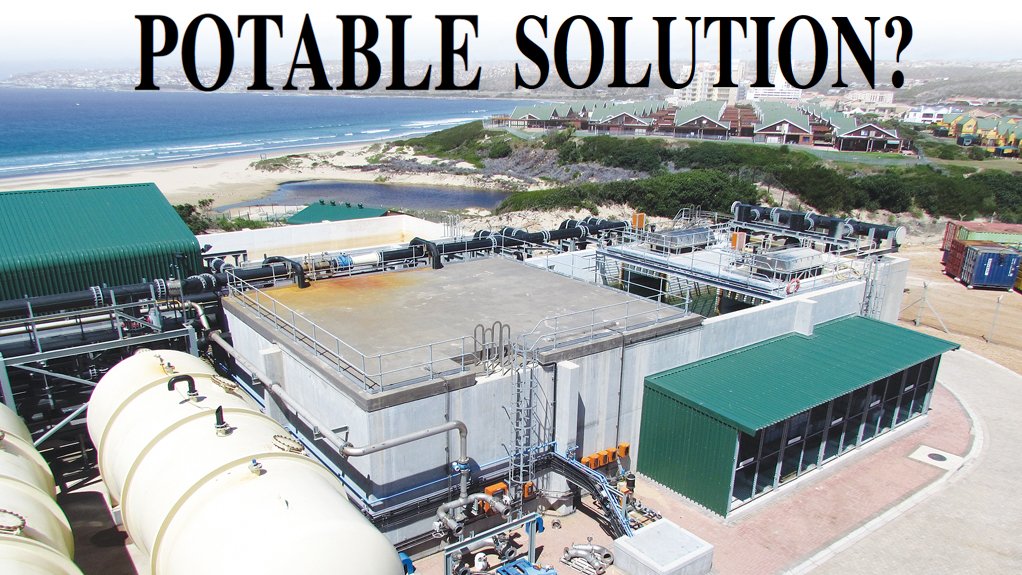

Veolia has, to date, constructed seven RO desalination plants in South Africa, the largest of which is the Mossel Bay plant, in the Western Cape. The plant can produce 15 Mℓ a day, of which 10 Mℓ is potable water and 5 Mℓ is industrial process water.

Domestic interest in desalination started in 2009 during several droughts in the country, with the first RO plant constructed in 2010, says Braybrooke.

Crucial to the success of RO plants is that they are not operated in a “stop-start” fashion. A common dilemma for large water utilities is that they rely on numerous sources of water (such as dams, rivers, boreholes and other water schemes) for potable bulk applications. When surface water is plentiful, it would make financial sense to shut down an RO plant and use conventional water treatment as a cost-saving measure, but this is not advisable, owing to desalination plants being developed to operate 24/7.

“We have determined that it is best to operate desalination plants throughout the year,” says Braybrooke. Veolia has entered into build-and-operate contracts, which include maintenance and operation, for most of its local plants, which is one way of “really enhancing the functionality of the plants and helping to reduce costs”, he adds.

CAPE TOWN SCENARIO

There is severe drought in the Western Cape, and desalination technology is being considered as a highly viable solution to ensure future water sustainability.

City of Cape Town informal settlements, water and waste services and energy MMC Councillor Xanthea Limberg tells Engineering News the municipality’s plans of potentially partnering with the private sector to create a short-term emergency water supply using desalination, stormwater capture or aquifer extraction are “progressing well”.

Although it is “too early” to provide more detail regarding further plans for desalination, the city is accelerating the construction of a small pilot plant for data collection purposes, she adds. Limberg says this plant will “pave the way for accelerated full-scale implementation”.

The city is also exploring rental land-based and offshore modular desalination units, which will potentially be installed at “strategically suitable locations”, in line with various technical and environmental requirements, and to facilitate effective supply into the reticulation network, she points out.

Limberg says long-term planning also includes a large-scale desalination plant – of between 150 Mℓ/d and 450 Mℓ/d – to be implemented in accordance with the city’s long-term water requirements.

She explains that the city’s water planning strategy is 30 years in advance: “Because of good planning, we are in a great position to bring forward, in a responsible manner, emergency supply schemes, with the small-scale desalination plant being one of them.”

NUCLEAR TIE-IN

There is much debate about how desalination plants can be operated in conjunction with nuclear power stations, but not much is understood as to why this is the case and what the advantages are.

Braybrooke clarifies that the advantages of retrofitting a desalination plant to a nuclear power station pertain mostly to existing raw water intake and discharge infrastructure. “A significant amount of the cost of building a desalination plant at the coast can be saved through piggybacking on a nuclear power station’s intake and discharge lines out at sea.”

He adds that a typical nuclear power station, which uses cold seawater for cooling, has intake and discharge infrastructure which is overdesigned, thereby resulting in sufficient capacity for a desalination plant to draw water for purification purposes.

Further, skills transfer for desalination plant operators can also be expedited through locating such a plant near a nuclear power station, as there are skilled water technicians at the power stations.

Heated water from the power station can also be diverted to a desalination plant through heat exchangers as a form of energy recovery. This will reduce operating costs “slightly”, says Braybrooke.

Further, locating a desalination plant at a nuclear power station – such as Koeberg, which is rolling out a pilot desalination plant – is a major cost benefit, as additional land does not have to be acquired because government already owns the land.

WASTEWATER RECYCLING

The question of whether desalination is the most feasible option to ensure water sustainability is a tricky one, which Braybrooke answers with a “yes and no!”.

He says wastewater recycling “ticks all the boxes of what is good and sustainable”. It is much faster to implement and costs less to build and operate. Wastewater recycling also relies on existing infrastructure, making it more cost effective in terms of licensing and buying land.

Wastewater recycling diverts semitreated wastewater, after it has been processed by a wastewater treatment plant, to another more robust “polishing” plant to purify it into a potable state through several “barriers” of filtration and chemical dosing. Following this, the fully purified water can be fed back to the bulk potable water reticulation system and reused.

The potable water can be produced at about half the price of desalinated water, states Braybrooke. This slight increase in the price of bulk potable water derived from recycling wastewater can be factored into the current cost of bulk, conventionally treated potable water to make it more palatable for the consumer, he adds.

Wastewater can be recycled indefinitely, thereby creating a hypothetical closed loop system.

Further, the Department of Water and Sanitation (DWS) supports wastewater recycling; its optimism is reflected in the objectives set out in its National Water Resource Strategy.

DWS infrastructure operations chief director Leonardo Manus tells Engineering News that a master plan (to which he is contributing) currently being drafted by the DWS includes desalination and/or wastewater reuse as two highly viable options to assist in ensuring future water sustainability.

The plan aims to make the National Water Resource Strategy “workable”, and the first draft is scheduled for publication in October, he adds.

For wastewater reuse to be feasible, Manus says, existing wastewater treatment plants need to operate within the parameters of predetermined water output quality and sound economics.

Braybrooke and Manus stress, however, that the major challenge to implementing wastewater recycling is public perception and disapproval. Both advocate that a lot of work needs to be done to create awareness that the methods used are reliable and safe. “There needs to be investment in the social side before investment can be made in engineering wastewater reuse plants,” he says.

Several severe droughts have seen Namibia institute the largest wastewater recycling plant in the world – the 21 000 m3 a day Goreangab plant, in Windhoek, the country’s capital city. Through this water reclamation plant, which was built in 2001, 300 000 people are provided with potable water.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation