AIDC in partnership with Ford announce the first Automotive Incubation Centre Graduate

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

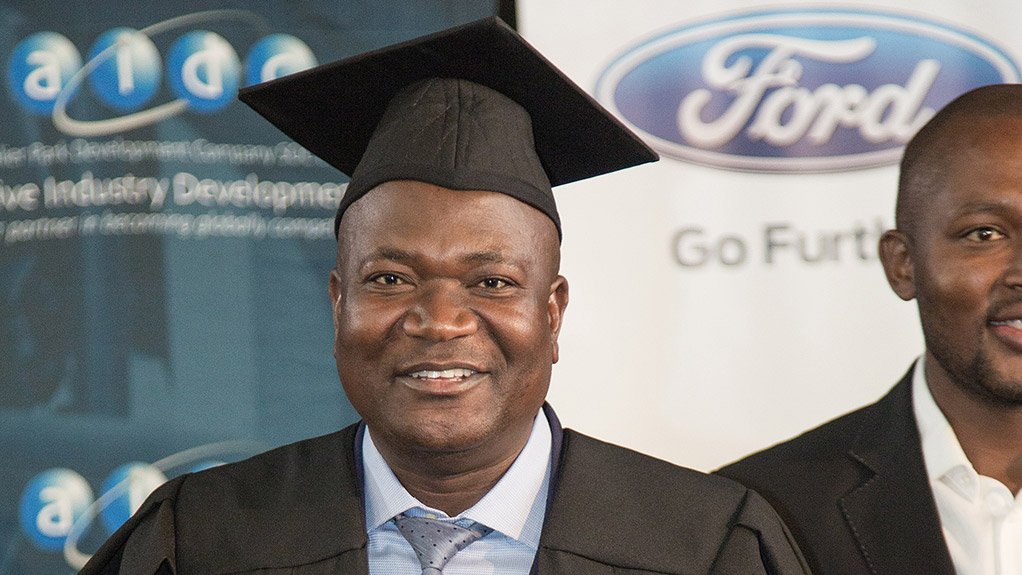

Company Annoucement - Caiphus Mokotedi is the first incubatee to graduate from the Automotive Industry Development Centre’s Automotive Incubation Centre at Ford Motor Company of Southern Africa’s Silverton Assembly Plant in Pretoria. Mokotedi, who owns and manages Zig Enterprise, met the minimum criteria required to graduate, and thus became the first graduate of the programme. The Automotive Incubation Centre was established to develop and support Black-owned businesses during the critical start-up phase which would then perform value-added sub-assembly work for Tier 1 suppliers on the Ford Ranger assembly. FMCSA’s Silverton assembly plant needed to transform from a low-volume, multiple vehicle line, to a single-model, high-volume production facility with an annual capacity of 110 000 vehicles.

Due to the nature of many of the components, FMCSA explored opportunities to reduce its overall production costs. A training and development plan, jointly conceived by FMCSA and the AIDC, led to the five-year plan to enhance the overall skills and knowledge base of automotive workers in Silverton, which resulted in a globally competitive workforce. The AIDC, in partnership with FMCSA, established five companies which were allocated to aspiring black broad-based economic empowerment (B-BBEE) entrepreneurs who could supply components to FMCSA’s production line. Mokotedi was one of the first BEE entrepreneurs who joined the incubation programme in 2011.

To accelerate and maximise the growth of the B-BBEE companies, the AIDC facilitated the process by establishing partnership agreements with the relevant Tier 1 Suppliers already earmarked to supply FMCSA with components for the Ford Ranger. The B-BBEE entrepreneurs are housed at the AIDC-owned and managed facility, which enables them to supply to Ford’s production line directly. Zig Enterprise partnered with Schnellecke SA to provide sequencing and logistics services along the Ford Ranger production line. Speaking at the graduation ceremony, Caiphus Mokotedi said that he was honoured to graduate from this facility. “There have been many highs and lows over the last four years. It has been an incredible journey and a milestone in my personal and professional life,” said Mokotedi. “During our start-up phase, there were many challenges that we needed to overcome, but through motivation and perseverance, we overcame these challenges,” he added. Lebogang Maile, MEC for Economic, Environment, Agriculture and Rural Development, highlighted that private-public partnerships were instrumental in fast-tracking Gauteng’s economy under the provinces Transformation, Modernisation and Re-industrialisation programme.

“We welcome working with vehicle manufacturers such as Ford in developing scarce skills, expanding the local supply chain, and providing opportunities to B-BBEE companies to create jobs,” said Maile. “The Incubation Centre has demonstrated that private-public partnerships can develop B-BBEE businesses,” he added. Dineshan Moodley, AIDC Executive: Industry Development, said that the aim of the Automotive Incubation Centre was to reduce the barriers to entry for entrepreneurs in the automotive industry. “One of the biggest challenges for entrepreneurs is start-up capital because they require large investment to enable them to participate in the value chain,” he explained. Moodley added that SMMEs who previously did not have the experience to supply components to their production lines, gained this experience at the Automotive Incubation Centre and were able to develop their business portfolio.

Jeff Nemeth, President and CEO of Ford Motor Company Sub Saharan Africa region, explained that the AIDC’s Automotive Incubation Centre is a phenomenal example of government and the private sector working together. “This was a vision that AIDC and Ford brainstormed about six years ago”, Nemeth said. “The AIDC built the 7 200m² Supplier Incubation Facility through a joint initiative between Ford, the Gauteng Provincial Government and the Tier 1 Suppliers who directly supply Ford in South Africa. The incubation centre is a B-BBEE initiative that has developed small businesses and aided economic growth,” he added.

Dr David Masondo, CEO at the AIDC, explained that transformation in the automotive sector is moving at a very slow pace, largely due to the very high barriers to entry for prospective new suppliers. “The Automotive Incubation Centre has proven to be an overwhelming success because we have reduced logistics costs of certain strategic sub-assemblies whilst also accelerating the transformation agenda through a well-managed and sustainable incubation process,” he said. Masondo congratulated Zig Enterprise on graduating from the facility and wished them well in their future business ventures. Zig Enterprise has already been contracted to FMCSA as a logistic services provider, and created 16 additional jobs in the process.

Key indicators of the project are as follows:

• The 7 200m² B-BBEE Automotive Incubation Centre has proven to be a success, considering its inaugural graduation ceremony.

• It is a first in South Africa and significantly expedites the transformation process in the key growth sectors within the province.

• Currently the facility has created 200 jobs and provides training interventions for 150 operators per year.

• The five B-BBEE companies (the sixth being the canteen operator) have been operational for the past four years and are currently supporting Ford in building approximately 300 vehicles per day, on a two shift strategy.

• One of the B-BBEE companies also produces components for export to a Ford manufacturing facility in Argentina.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation