AECOM completes work on Plankenbrug outfall sewer in Stellenbosch

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

As Lead Design Engineer, AECOM carried out construction monitoring of Phase 1 of the Plankenbrug Main Outfall Sewer and Associated Works in Stellenbosch. Construction commenced in October 2015, and was completed in March.

The new Plankenbrug Outfall Sewer replaced the three main outfall sewers servicing Stellenbosch town, from the Distillery Road bridge over the Plankenbrug River near Bosman’s Crossing, to the downstream Stellenbosch Wastewater Treatment Works off Vredenburg Road.

The existing outfall sewers ranged from 375 mm to 625 mm in diameter. An outfall sewer receives sewage from the collecting system, and conveys it to a point of final discharge, or to a disposal plant. “These outfall sewers had reached the end of their design lives, and a new outfall sewer was required urgently to provide additional flow capacity to the expanding Stellenbosch town,” AECOM Engineer Christian Jordaan commented.

The new outfall sewer has a total length of 1 815 m, which is made up of 45 m of 1-m-diameter and 1 770 m of 1.2-m-diameter pipeline. A length of 240 m was installed by means of pipe jacking underneath a foothill of Papegaaiberg. This avoided open-cut excavation to depths exceeding 10 m, thereby limiting disruption to the area and lowering construction costs.

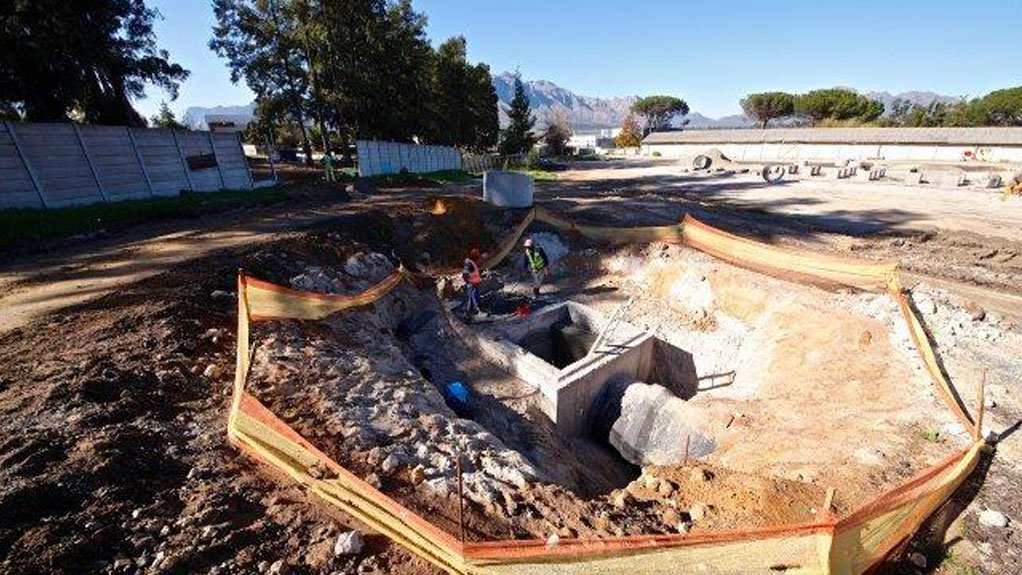

Using this method, the new outfall sewer was installed underneath a section of the Stellenbosch cemetery, containing a number of large trees, all which remained intact. The pipe jacking was carried out in three sections, which required the construction of three jacking pits. These pits, with a 6 m diameter, were constructed to depths of 5.6 m to 11.8 m.

Installation of the new outfall sewer included construction of manhole structures at roughly 90 m intervals, at lateral tie-in positions, and at changes to the outfall sewer alignment, to allow access for operation and maintenance.

Due to the limited vertical fall available between the upstream and downstream ends of the new outfall sewer, the outfall sewer had to be installed at depths that resulted in clashes with the existing outfall sewers wherever the outfall sewers crossed.

Specially-designed manholes were constructed at these locations, over the existing outfall sewer. The existing outfall sewer penetrated through the new manhole, and hence could remain ‘live’, without discharging into the manhole, until final connection to the new outfall sewer was made.

The manholes typically comprised an on-site cast concrete chamber (with benching) constructed below ground level, with an access chimney. Where depth allowed, working space within the manholes was optimised with the used of 1.8-m-diameter precast concrete rings as the access chimney.

An important aspect of the contract was the communication and liaison with the local community in terms of traffic accommodation, access to residences, security, noise, and dust. Temporary, or partial, road closures were managed continuously. In this regard, a Traffic Accommodation Plan was implemented as part of the contract.

An Environmental Management Programme was also implemented, which contained the procedures and requirements for the protection of the natural environment during construction of the new Plankenbrug Outfall Sewer.

“The project was completed on schedule, and within budget,” Jordaan confirms. “AECOM’s successful partnership with Stellenbosch Municipality and the JVZ Construction & Vakala Construction Joint Venture delivered a service that will accommodate all future developments efficiently, as estimated in the Stellenbosch Sewer Masterplan,” he concludes.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation