ABB technology to be used in world’s first open CO2 transport and storage infrastructure

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

ABB has been contracted by engineering, procurement, and construction (EPC) contractor Aker Solutions, a leader in sustainable energy solutions, to deliver the main electrical, automation and safety systems for Norway’s Northern Lights project.

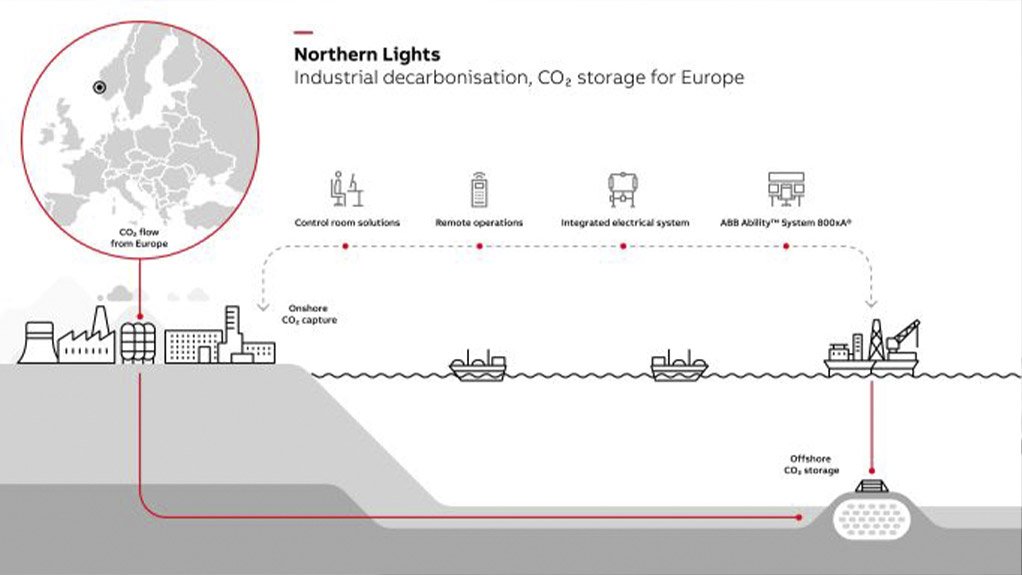

A joint venture between Equinor, Shell and TotalEnergies, Northern Lights is the first industrial carbon capture and storage project to develop an open and flexible infrastructure to safely store CO2 from industries across Europe. The first phase of the project is due to be completed mid-2024 and will have the capacity to permanently store up to 1.5 million tons of CO2 per year, with the ambition to expand to over five million tons per year in a second development phase.

ABB’s automation, electrical and digital solutions will be integrated into the Northern Lights project to enable the remote operation of a new carbon capture terminal and ensure that the facility runs at optimum efficiency.

Leveraging its market-leading distributed control system ABB Ability™ System 800xA, operators will gain greater visibility into the operation of the Northern Lights terminal, with the ABB system analyzing real-time and historical data and instantly showing plant metrics and KPIs. As a result, operators will be able to make more accurate and informed decisions and review options for optimizing performance of assets and processes.

“ABB is both a market leader in distributed control systems and a long-standing partner with a thorough understanding of our business and expertise in both on- and offshore as well as subsea projects,” said Kristin Glenna, project manager for Northern Lights at Aker Solutions. “This was key to our decision-making process. We needed to entrust our remote operations to a partner with a successful track record in reliability and optimization to provide strong foundations for this important development.”

“The ability to capture and store industrial CO2 emissions, which cannot currently be prevented, is critical if the world is to reach net zero by 2050 with a global capacity of 1.7 billion tons of CO2 capture re-quired by 2030[1],” said Per Erik Holsten, Head of ABB Energy Industries in Northern Europe. “Northern Lights is an important development not only for its contribution to rebalancing the carbon cycle, but also for its commitment to innovation. We are very pleased to be part of this exciting project that will contribute to a safer, smarter and more sustainable future.”

Purpose-built ships will transport captured and liquefied CO2 from emitters to the Northern Lights Øygarden Terminal in western Norway, which will be remotely operated from Equinor’s facilities at the Sture Terminal located approximately 7 km away. To enable remote operations, ABB will build a state-of-the-art Extended Operator Workstation at the Northern Lights Terminal which will work in tandem with the central control room in Sture, with the two communicating seamlessly to minimize response times and support 24/7 remote operations.

ABB technology will also power the entire project, apart from the shore-to-ship solution, implementing the main electrical system via its power process management system and incorporating high and low voltage switchboards and transformers.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation